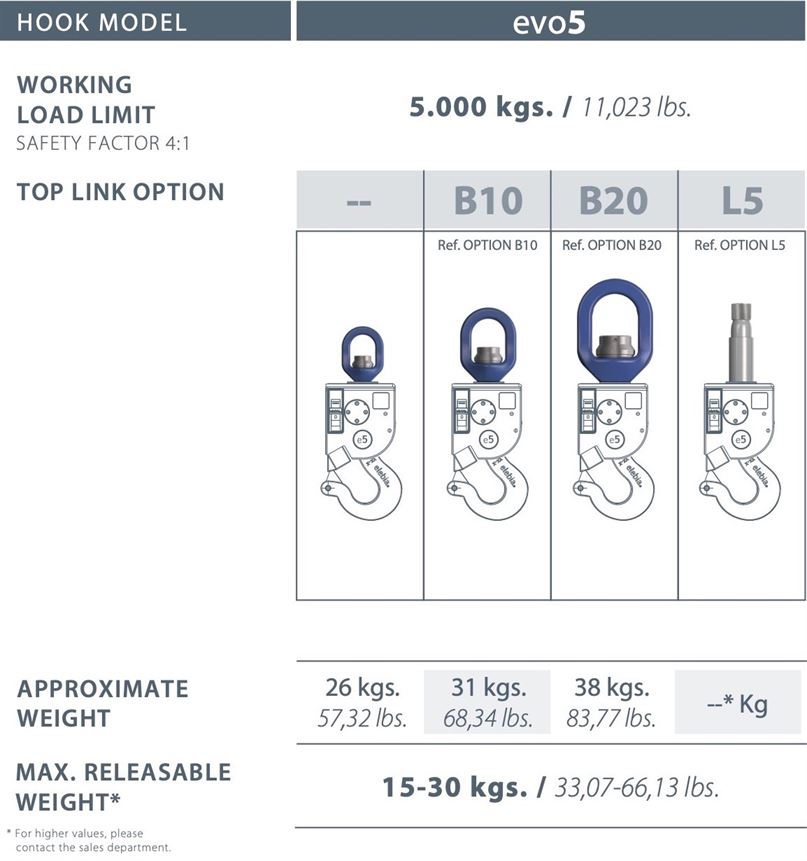

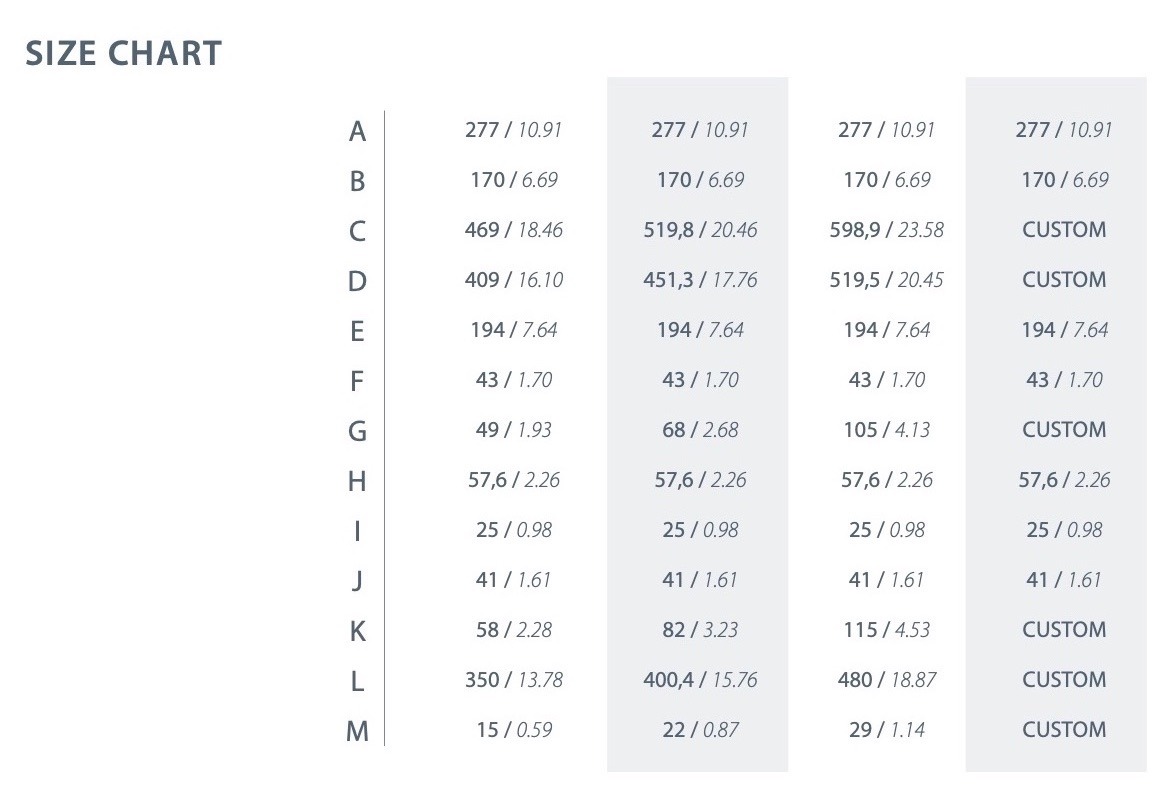

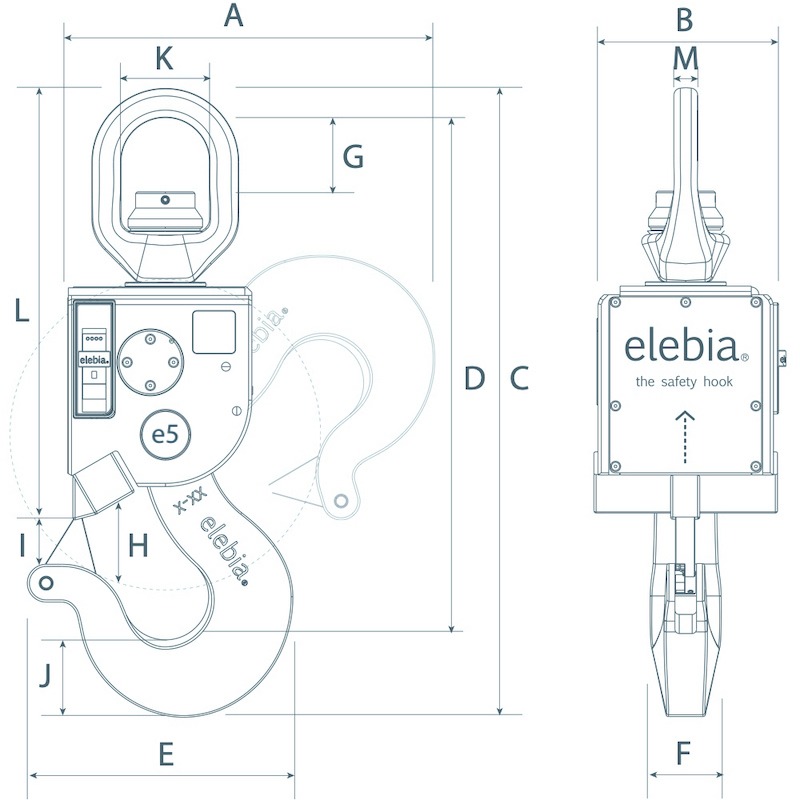

Lifting Hooks for Cranes

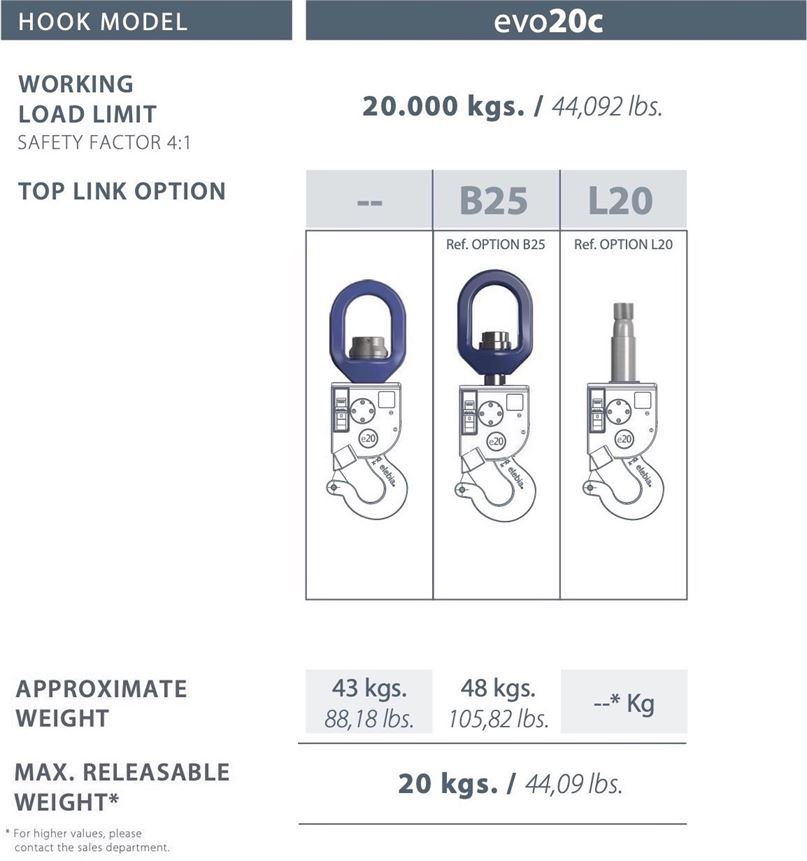

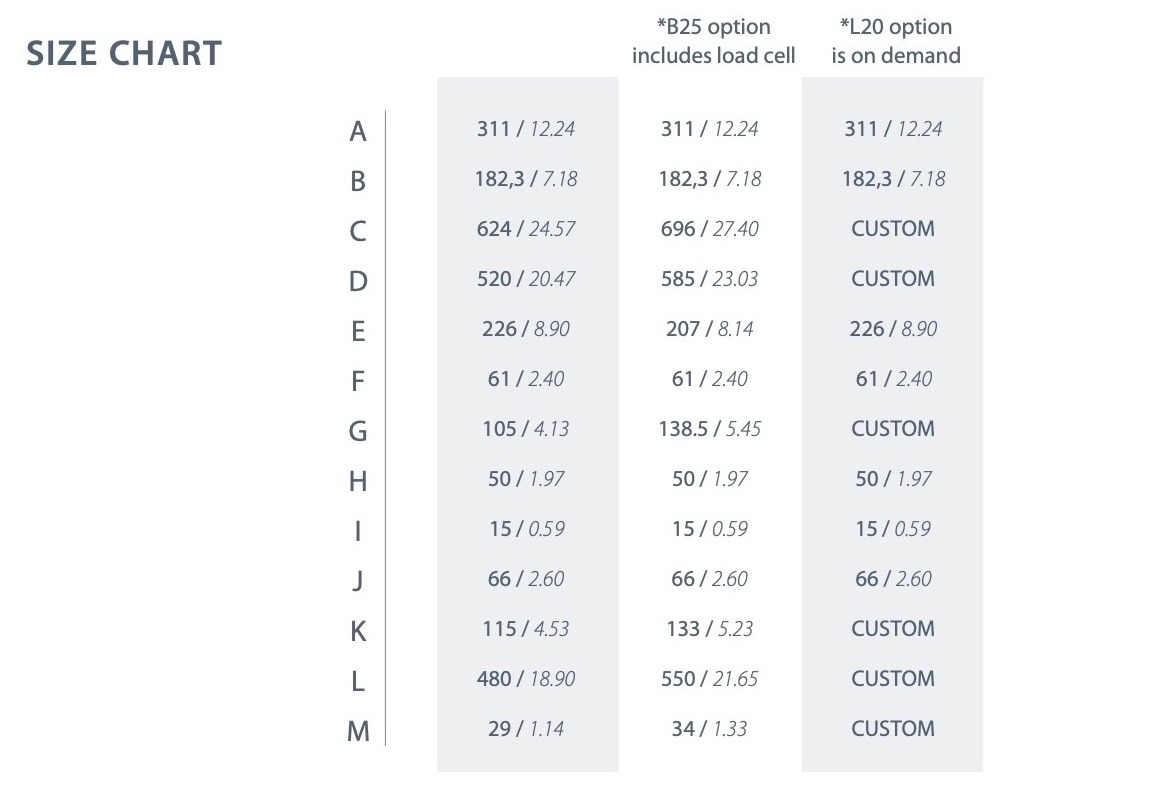

With the evo range of lifting hooks for cranes, elebia, the market leader in automatic lifting solutions will boost the safety and productivity of your cranes. The patented evo hooks range from the 2.5 tons capacity of the Automatic Crane Hooks to 25 tons capacity and allow you to hook on and release any load remotely.

Our evo5-evo25 crane lifting hook selection has been designed with one purpose: to bring our customers multiple options that can fit the needs of the heaviest lifting operations. No matter what kind of cargo you need to carry, it will be easy for you to find the perfect solution.

The patented range of safety hooks are equipped with a magnet in its lower section. When the magnet is close to the load, it attracts and correctly positions the sling. The operator pushes the control button, the hook closes, catches the ring and lifts the load without any additional handling.

These crane hooks work with cable slings, chains slings, master links, textile slings and even big bags. And with the unique elebia hooks, you will be able to pick up and release loads remotely, avoiding any handling and moving, minimising risks, enhancing safety and increasing productivity.

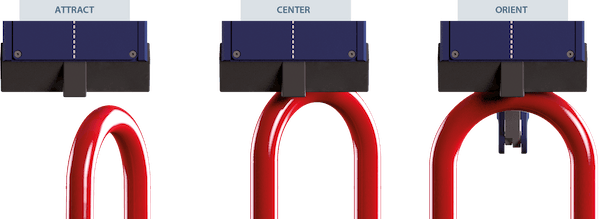

How Does It Work?

The evo lifting hooks attach and release the load remotely. The remote controlled crane hooks generate a magnetic field that

1. attracts the rigging gear or lifting accessory…

2. …orients it…

3. …and centers it.

The operator then presses the “close” button on the remote control to automatically close the lifting hooks for cranes, without any manual intervention, and operating remotely from a safe distance.

Check out out Youtube channel for more videos on how the patented evo lifting hooks engage and release any load remotely in different applications and in different industries.

Smart

A sensor in the magnet indicates when the ring is in position. All this information is recorded in the eMAX remote control that acts as a hub gathering all the information and recording all the activity of the hook.

Efficient

We’ve redesigned the high-capacity battery to improve efficiency and minimise energy consumption of the hook. The battery is fully charged in 3 hours, and allows up to 5,000 cycles or 250 hours in standby mode.

Powerful

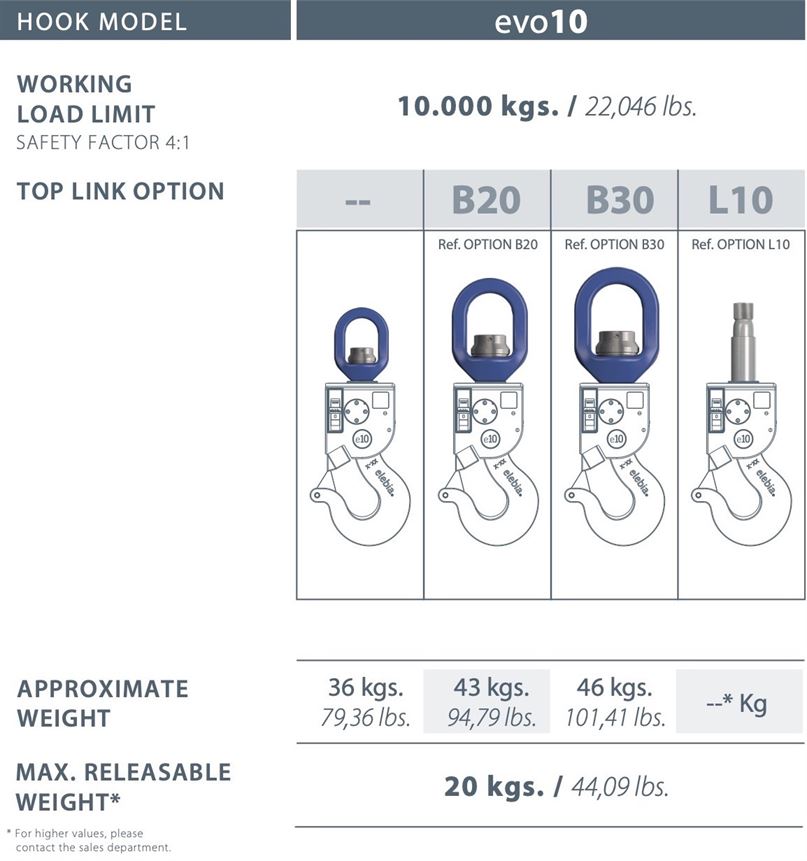

The new gearmotor allows you to release up to 20kgs. (40.09 lbs.) There will be no more problems with heavy rigging and with the precise electronic torque control, you can adjust the release limit. It is also clutch protected from overloads.

Tough

Designed to work in the toughest conditions (steelworks, ports, low temperatures) and built with the best materials. WELDOX body of high strength steel, forged hook type T or V.

Fail-safe Designed Lifting Hooks for Cranes

The evo range of lifting hooks for cranes was designed to enhance safety and increase productivity. It is designed under a fail-safe principle. Most importantly, this hook CAN NOT drop a suspended load. This is a feature of all our designs, geometrically fail-safe, without any sensors or electric components.

Latch

The evo5 to evo25 crane hooks can be configured with a spring latch or with a rigid latch. Learn more

Range

For information regarding the evo2 crane hook, click here: evo2

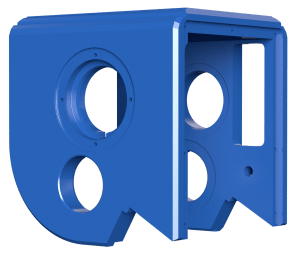

Magnetic System

Our crane hooks come with a unique magnetic system, formed by 32 neodymium permanent magnets. These magnets are placed in a precise configuration that generate an oriented magnetic field with 3 functions: attract, center and orient the masterlink.

The complete range of our hooks carry this basic component, which allows the remote engage of loads.

Other options can also be configured with the crane hooks.

Standard Magnet

REF.: STANDARD MAGNET

The standard magnet is composed of 32 permanent magnets that build up a magnetic field and perform the three functions that characterise the elebia hooks. It attracts the target, centres it and orients it to the ring. This is the basic component that allows the remote hooking of loads thanks to an off-site control.

Magnet Sensor

REF.: OPTION S

A sensor in the magnet indicates when the masterlink is attached to it. This info is displayed in the eMAX remote control. Units with the magnet sensor can be configured in ‘Autoclose Mode’: the hook will automatically close when the magnet sensor detects the ring is in position. The magnet sensor’s sensitivity/trigger level can be adjusted to customer needs.

Power Magnet

REF.: OPTION PM

Increased magnetic power.

Void, No Magnets

REF.: OPTION V

No magnetic system.

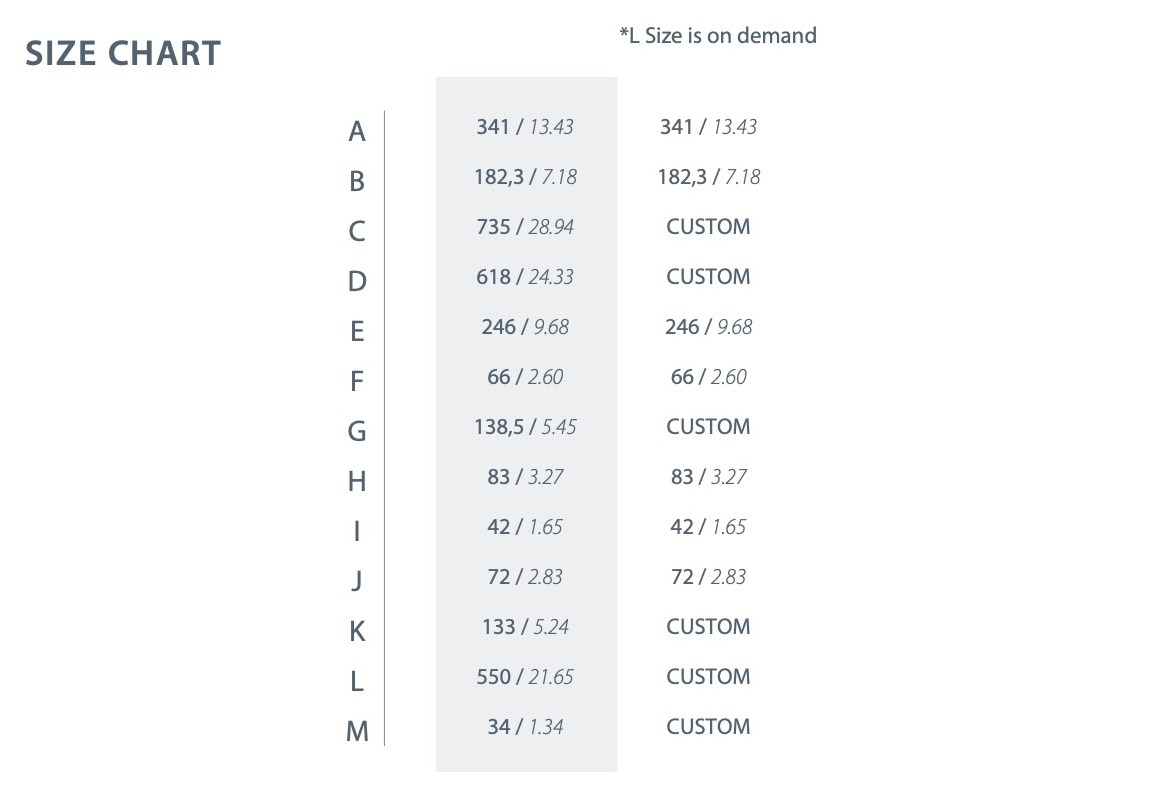

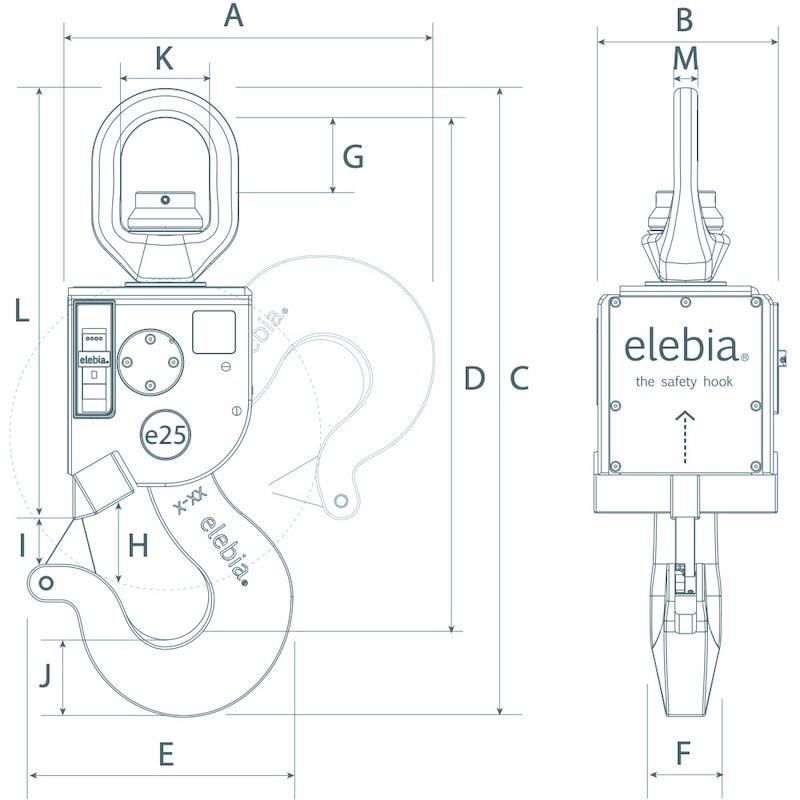

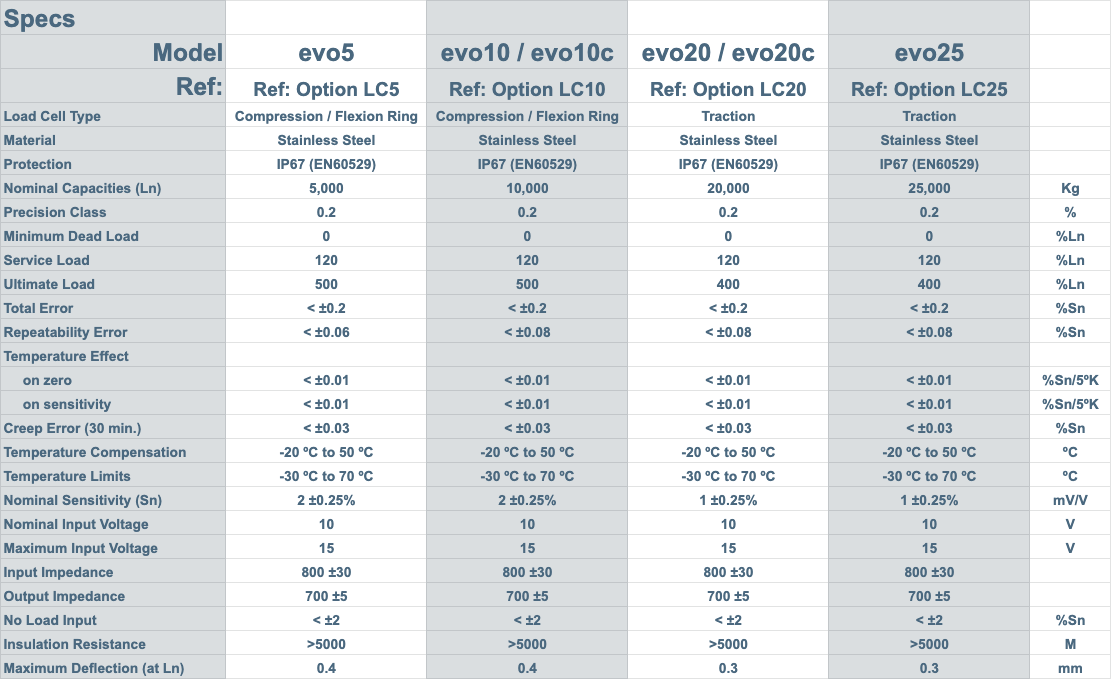

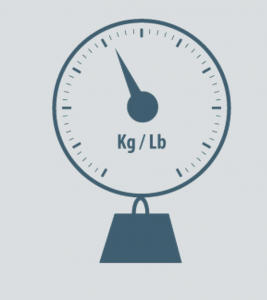

Weighing Scale

The complete range of quick release hooks for cranes can be upgraded with a load cell to weigh the load that is being lifted. This cargo cell is accurate, powerful and fully integrated into the hook, representing no increase in weight or dimensions of the unit.

The load cell is highly recommended for preventing overloads and as an additional safety hooks lifting measure. Load cells can also be retrofitted into older models of our crane lifting hooks.

The load cell in combination with the eMAX remote control transforms all of our load hooks into a precise weighing scale with advanced features.

Option Alarm

An acoustic alarm & warning can be configured if necessary (100dB at 1m), and it will trigger itself under the following scenarios:

– When exceeding the load capacity and/or pre-set weight limit of the Warning on the eMAX remote control set in Settings -> Emax -> Scale -> Alarms -> Warning (On) -> Value -> (Set value)

– In case of an unbalanced load, configured on the Differential of the eMAX remote control, set in Settings -> Emax -> Scale -> Alarms -> Differential (On) -> Value -> (Set value)

In both cases, the acoustic alarm & warnings (buzzer, vibrator) will deactivate themselves automatically once the excess weight is ammended and/or when the load is correctly balanced.

Position Encoder

The innovative position encoder has been integrated into the complete range of evo lifting hooks for cranes. As a result, this represents an added safety element in all lifting operations. The encoder highlights a technical upgrade of our remote hooks, as it allows to know the exact angular position of the hook at any given moment thanks the information relayed to the eMAX remote control.

This important feature comes in very handy in operations where the operator can not see the hook’s position. The crane hook status is displayed on the eMAX remote control, transmitting real time information to the operator.

With the position encoder and the eMAX remote control, the user is always aware of the hook’s status (open/closed) and is informed with the buzzer/vibrator and display features of the eMAX if the load is not placed correctly on the safety hook. (e.g. tip of the hook)

With the specifications of this advanced feature, the chances of impacts are reduced, the life-span of the motor and clutch increase and most importantly, safety is enhanced in all lifting operations.

The position encoder can be retrofitted into older units of the complete range of evo lifting hooks for cranes (except for versions with a spring loaded latch)

Remote Controlled

Simply open and close the crane hooks or receive real-time information of weight, battery level, and other values of the lifting and manoeuvring operation.

As with the rest of our lifting products, the crane hook can be paired to the eMAX, eMINI and/or eINST installable remote controls.

All of them allow a simple, flexible, precise and reliable control in a fail-safe way.

evo5-evo25 Bumper with LEDs

With safety always in mind, the new evo5-evo25 Bumper, which protects the hooks from impacts, now also carries a LED status indicator, which shows the lifting hook’s status at all times with a 4 colour colour-code scheme visible from the operator’s position.

Built from flexible silicone rubber with 70 shore A hardness, rigid and durable enough to absorb multiple and heavy impacts.

The bumper with LEDs can work from temperature ranges of -40ºC to 200ºC / -40ºF to 392ºF

Reinforced battery cover.

The new evo5 to evo25 bumper with LEDs can be retrofitted into older units and has a very simple installation.

It is NOT valid for the evo2 hook or hooks with counterbalance.

evo5-evo25 Bumper

The bumper for the lifting hooks is the perfect shock absorber that protects the safety hooks from impacts, scratches and day-to-day wear.

Built from flexible silicone rubber with 70 shore A hardness, rigid and durable enough to absorb multiple and heavy impacts.

The bumper can withstand temperature ranges of -40ºC to 200ºC / -40ºF to 392ºF

Reinforced battery slot protection to prevent the battery from accidentally falling.

The evo5 to evo25 bumper can be retrofitted into older units and has a very simple installation.

It is NOT valid for the evo2 hook or hooks with counterbalance.

Special Environments

The standard crane hook units are rugged, designed and built to work in almost every industry. For special environments, you have the following options:

Marine

Marine environments are highly corrosive and need adapted durable lifting hooks to guarantee functionality.

We use C5M paint and AISI components to keep devices free from corrosion in marine areas where they’re susceptible to salt damage.

C5M Painting and AISI components.

Recommended for:

Marine Environments

Industries:

Offshore Wind Turbines, Onboard Cranes, Buoys

More Info here

DNV

Our evo5, evo10 and evo20 lifting hooks all comply with DNV GL standards for shipboard and offshore lifting devices. This confirms the safety and reliability of our devices in these environments.

DNV 2.22 certification for Offshore lifting appliances.

Recommended for:

Offshore Operations

Industries:

Offshore Wind Turbines, Onboard Cranes

More Info here

ATEX/IECEx

Lifting hooks with ATEX/IECEx certification are considered safe to use in explosive production or in atmospheres where there’s significant risk of explosion.

Units with IECEx certification for zones 1 & 21 according to European Directive 2014/34/EU and IECEx international standards.

IECEx certification to work on sites classified as zone 1 & zone 21 according to the European Directive 99/92/EC and IECEx international standards.

Recommended for:

Operations in potentially explosive atmospheres

Industries:

Oil & Gas, Mining & Chemical

More Info here

Heat Shield

Heat shield that protects the crane hook and its electronic components from radiated heat and extended temperature working range.

Although elebia lifting hooks are highly durable and can be adapted to any situation, environments with extremely elevated temperatures require a heat shield for the device. This heat shield is made with a galvanised surface treatment and is compatible with all our lifting hooks, except evo2.

Recommended for:

Operations where the lifting crane hooks are subject to extremely elevated temperatures and radiated heat

Industries:

Foundries

More Info here

Regulatory Standards

The evo range of hooks for cranes certify with the following regulatory standards:

| ASME B30.10-2009 | UNE-EN 60204-1:2007 | D89/391/EEC |

| ASME B30.20-2010 | UNE-EN 61000-6-4:2007 | D89/654/EEC |

| UNE-EN 1050 | UNE-EN 61000-6-2:2006 | D89/655/EEC |

| UNE-EN 1677-1:2001 + A1:2009 | UNE-EN ISO12100:2012 | D89/656/EEC |

| UNE-EN 1677-2:2001 + A1:2008 | EN 10204 3.1.B | D92/58/EEC 9a |

Directive on Machine Safety (D2006/42/EC).

EMC Directive (2014/30/EU).

Low Voltage Directive (2014/35/EU).

Radio Equipment Directive (2014/53/EU).

Assurance of Production Quality in accordance with ISO9001.

DNV GL Certified (evo5 / evo10 / evo20).

ARIB Construction Design Certification Number 203-JN0689.

FCC Identifier 2ACLHEVO for Equipment Class: Digital Transmission System.

Each mechanism is delivered with the CE stamp and a declaration of CE conformity.

elebia is a member of F.E.M. (European Federation of Materials Handling).

Quick Links

Hook Configurator

Personalize and configure

your lifting hook for cranes

and any of its accessories.

Schedule a Demo

Need or want to see in

person which crane hook

best fits your needs?

Quick FAQ’s

What materials are used in producing crane hooks?

Generally crane hooks are made from iron or steel. Some common materials used include carbon steel, alloy steels, wrought iron, HSLA (High Speed Low Alloy), chromium steel, stainless steel and gray cast iron.

Are safety latches required on lifting hooks?

When deciding on whether to use a hook latch or not, careful consideration must be given to the specific lifting application. At elebia, our hooks can carry one of two options: either a spring loaded latch or a rigid safety latch.

What is the lifting capacity of the evo range of this crane hooks?

The patented evo hooks range from the 2,5 tons capacity of the evo2 crane hook to 25 tons capacity and allow you to hook on and release any load remotely.

What is the purpose of a lifting hook for cranes?

Lifting hooks connect to cranes or other lifting points and accessories to manoeuvre loads. They are used in many industries and the ideal crane hook for your needs depends on the weight of the load that is being lifted, the material that is being lifted, lifting points, amongst other factors.