evo patented Crane Hooks

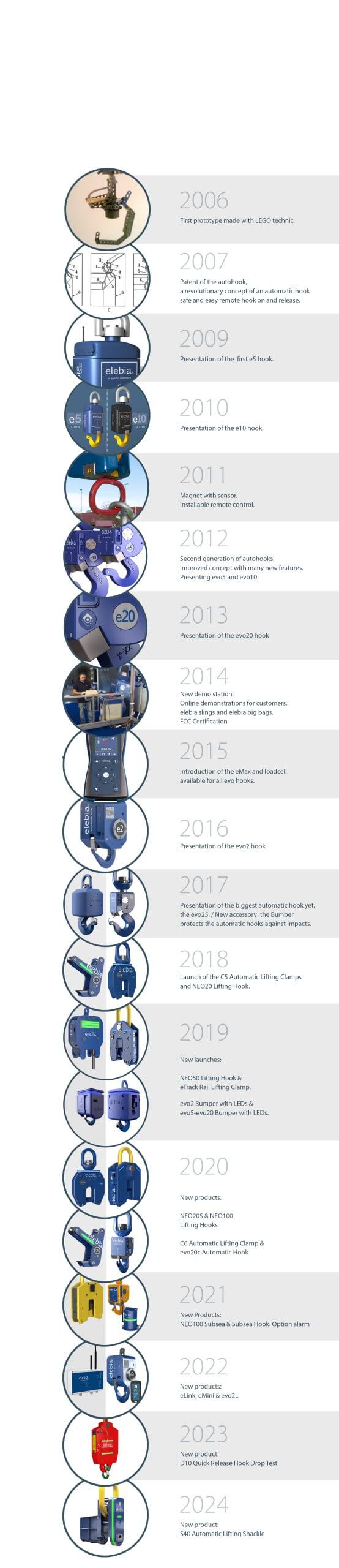

The concept kept constantly growing and advancing. In 2010, we presented the e10, but there was always something to do and something to improve. In 2012 we came out with our second generation of automatic crane hooks. These were much more compact and improved in many ways, and renamed as «evo«. The following year, the evo20 was presented and the load cell was incorporated onto the hooks, increasing its functionality.

In 2015 we presented the eMAX remote control, the natural evolution of our remote control. It included a big full color LCD display and gave important information to the user that was, until then, unavailable. Different alarms (overload and unbalance), weight, hook status, and much more…

After the evo5, evo10 and evo20, in 2016 came the revolutionary evo2 crane hook. A much more compact, lighter and more sophisticated lifting hook able to lift up to 2,500 kg/5,511 lbs. Just like its bigger brothers, it was able to engage and release loads remotely within a fail-safe design that makes it physically impossible to drop any load during operations.

2017 saw us present the biggest, strongest and toughest automatic hook yet, the evo25, with a lifting capacity of up to 25,000 kg. (over 55,000 lbs.). We developped new accessories like the Bumpers, designed to protect the complete range of automatic crane hooks from all sort of impacts, increasing safety and productivity in all operations across every industry.

New Products

The most innovative launches for our company were in 2018, with the C5 Automatic Lifting Clamps, exclusively designed for the lifting and moving of steel plates, beams and/or pipes, and the NEO20 Lifting Hook. These two new and revolutionary products represented new solutions in the lifting industry. It also consolidated our position as the market leader in automatic lifting solutions and equipment.

In 2019 we launched the NEO50 Lifting Hook and the eTrack Rail Lifting Clamp. And we’ve also updated our Bumpers with LEDs for both the evo2 automatic crane hook and the evo5-evo20 range.

2020 was prolific in broadening the range of our lifting solutions as we launched the NEO20S and NEO100 lifting hooks, increasing the lifting capacity to up to 100,000 kgs. (220.462 lbs.) The C6 lifting clamp and the evo20c (compact) crane hook have also seen the light this year.

In 2021 we embarked on very specific client-oriented projects with the launch of the Hookbot, the remote-controlled robot for lifting in offshore platforms, and the Subsea Hook, a solution for carrying out loading and unloading operations in subsea environments.

Thanks to our innovative range of remote automatic crane hooks, automatic lifting clamps, NEO range lifting hooks and accessories, we are drastically improving productivity and safety of global leading companies such as Rolls-Royce, Space-X, ArcelorMittal, Boeing, Airbus, Siemens, Tenaris and many more.

The Future…

Our goal is to increase our range of automatic hooks, adding new features to increase safety and productivity. And along with our Research and Development team we are developing new products and accessories that will enhance even more lifting operations worldwide and bring new solutions to different industries.

If you want to learn more about our products and be up to date with our latest news, subscribe to our Newsletter.