Types of Bell Furnaces

4 October, 2018

Types of Bell Furnaces

A bell furnace is necessary when the industrial process for which it is being used requires an enclosed atmosphere. There are different types of bell furnaces in the market, and the process for which the furnace is needed could be carburising, ferritic nitro carburising (FNC) or gas soft nitriding (NSF). But we must understand that all bell furnaces are not constructed in exactly the same way.

These furnaces are required when the industrial workload is very high in that particular plant or factory. They do not handle small batches. While they may have that bell shape in common, they may all powered in several different ways. We will now explore the different types of bell furnaces in order to clarify this matter.

A Summary of Types of Bell Furnaces

As mentioned above, there are several different types of bell-type furnaces available. All have their positive and negative points. The types of bell furnaces, if referred to the heating process, are the following:

- Electrically Heated Bell Furnace. Furnaces which are powered by electricity are often thought to be more power efficient than gas-powered electric furnaces. This may be the case. However, the consideration to install gas or electrical powered furnaces are often motivated by considerations other than the saving of money. The process which is going to be carried out is the main consideration.

- Gas fired Bell Furnace. This is generally considered to be less efficient than an electrically powered furnace but as mentioned above, the choice of gas-powered or electrically powered furnaces comes down to the type of process for which the bell furnace is needed. Depending on the process, gas or electricity may be better.

- Thermal Recirculation Systems in Bell Furnace. If this feature is present, then the furnace is more economic and less susceptible to heat loss. Which makes the product more efficient and cost effective. Which is better both for the environment and for the customer.

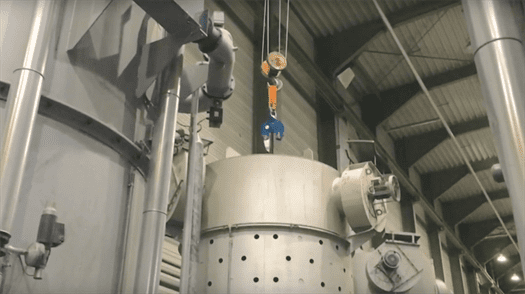

Installation of Bell Type Furnaces

One of the most difficult matters regarding the installation of a bell type furnace is manoeuvering the equipment into its correct place and position. That job is an engineering feat in itself. The furnace will not be light and its placement will give the manufacturer some headaches. This is why the elebia NEO lifting hook for bell furnaces is such a boon. This specially designed hook works in harmony with the crane to support the furnace and its weight. It also has the smarts to lift the bell furnace correctly into its vertical position. It’s a smart lifting solution to a major problem. The hook is strong enough to support the weight of the furnace and it has the strength and manoeuvrability to get the bell furnace into the correct position. This will help opeartors do their job far more efficiently, cost-effectively and safely.

A Safety Problem

Bell furnaces are lifted dozens of times every day, from one end to another in order to complete the industrial process. Every lift of a bell furnace implies a series of risks that are inherent to the job. Operators need to work from a safe distance with the elevated temperature range that these appliances withstand which implies having limited visibility of the bell furnaces’ lifting point as it is found centered at a very elevated height. To top this off, the lifting hooks that are used in this lifting process are not set-up with a safety latch.

Let’s not kid ourserlves: everybody is aware that more accidents that we’d like to recognise have occurred in the transportation of bell furnaces because of the difficulties associated to the handling of this appliance… But, just because the risks are there, this does not mean they can’t be dealt with.

Newsletter

Sign up for our newsletter and get the latest news from elebia

The Solution

The NEO20 lifting hook for bell furnaces has been designed, like the rest of our products, under a fail-safe principle: therefore it is impossible to drop a suspended load. Safety first!

The lifting hook orients itself automatically ensuring it is correctly positioned on the lifting point, detecting the load is in position and closing automatically, with no additional handling involved. It’s tip, once closed, forms a complete loop around the lifting point, the closure system is confirmed locked and the bell furnace is ready to be lifted.

The NEO20 is ideal for oversized lifting points (up to 100mm Ø) and allows the remote engage and release of the load. Additional features such as the Autoclose Mode & the LED status indicator only add more safety measures to ensure that the process of lifting these appliances are handled in the most safest and controlled environment posible. It is therefore legitimate to confirm that the especially designed lifting hook for bell furnaces will save industry time, money, increasing efficiency and cost-effectiveness.

But most importantly, it represents the smartest and safest solution to the risks associated with the lifting of bell furnaces.

Products Made For Your Company

Discover the NEO20 Lifting Hook