5,000 kgs./11,023 lbs. lifting capacity and a safety factor of 4:1 (C5)

6,000 kgs./13,227 lbs. lifting capacity and a safety factor of 3:1 (C6)

The life span of the C6 automatic lifting clamp is limited to 20,000 lifts. (UNE-EN-13155)

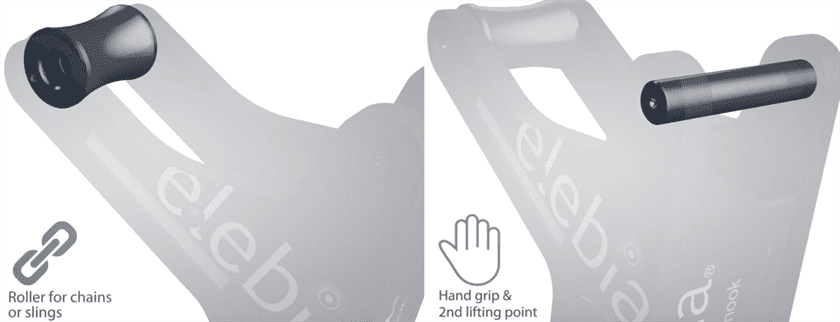

Roller for Chains

Hand grip that can be used as a second lifting point

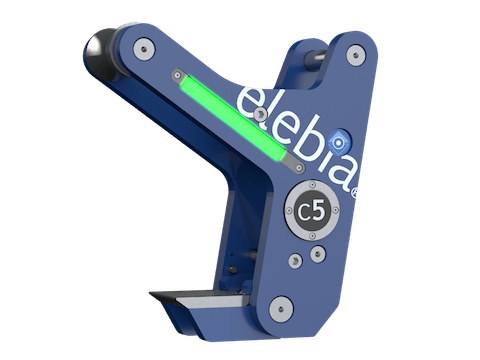

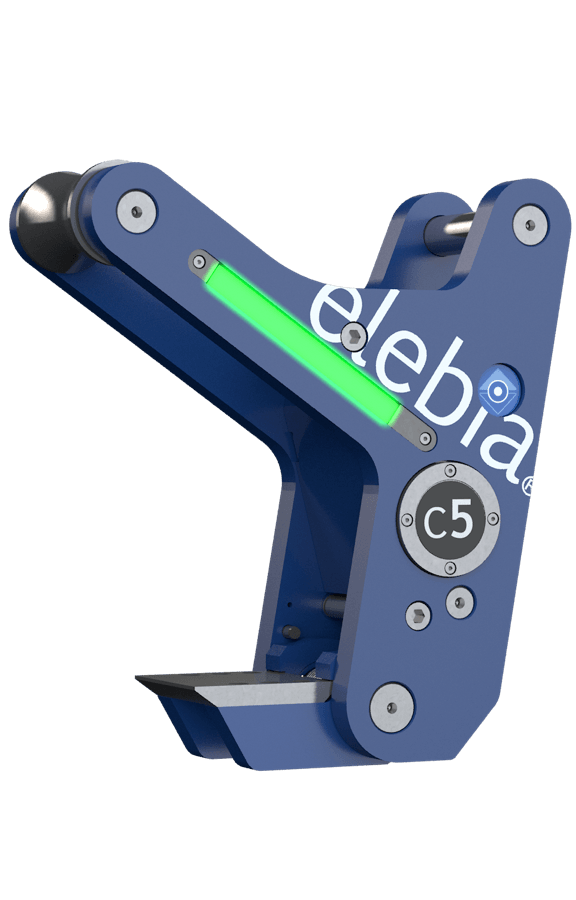

High-Brightness LED Status Indicator

¡Check out our Rail Lifting Clamps for cranes!

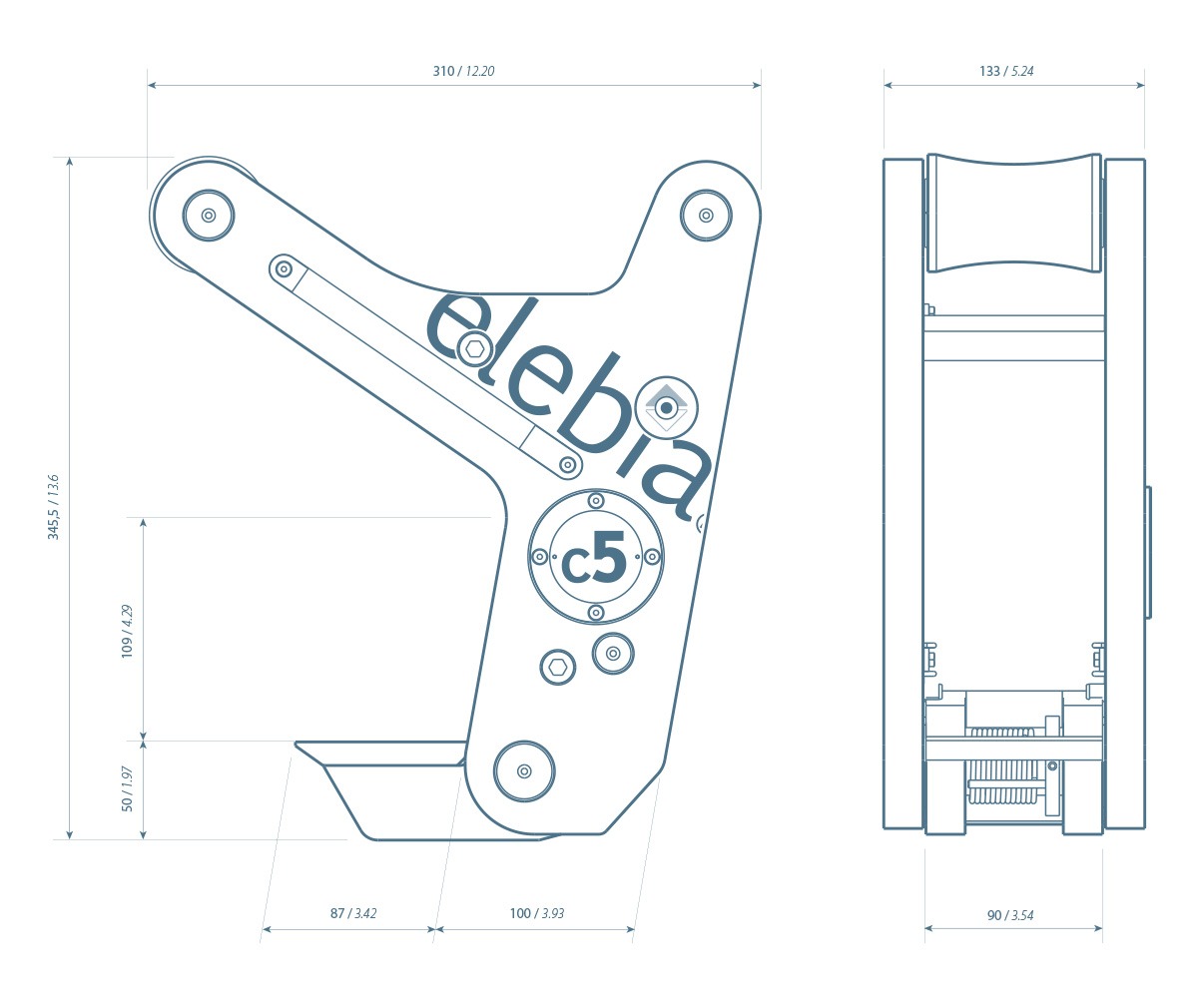

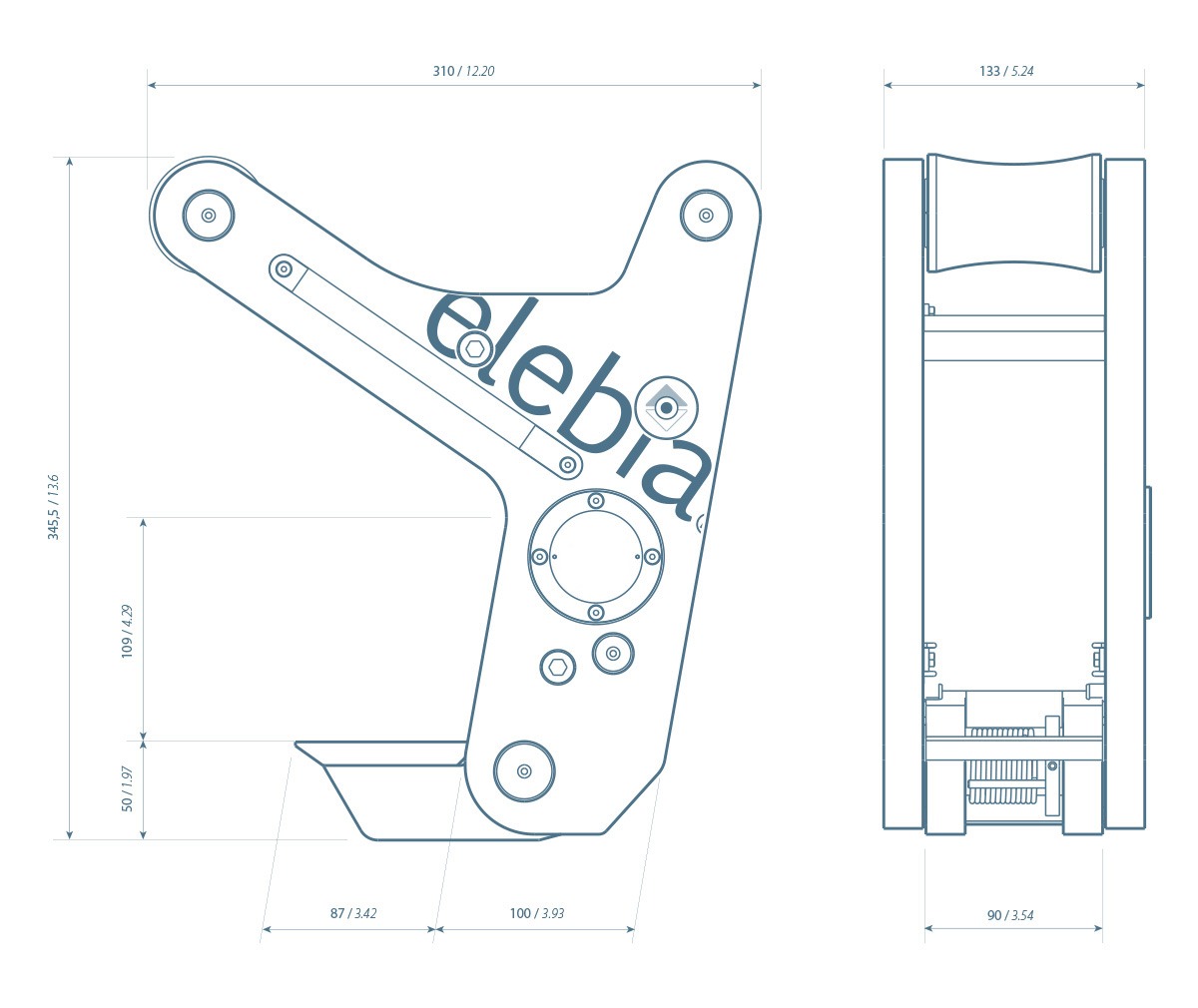

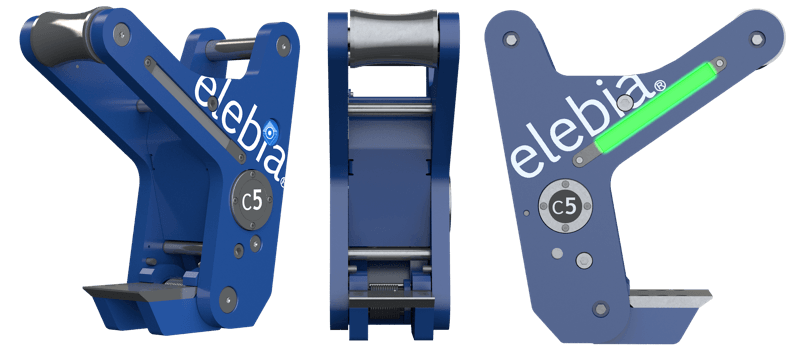

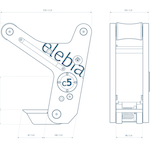

Main Specs of the C5 & C6 Lifting Clamps

Horizontal Lifting Clamps: Efficient and Safe

The C5 & C6 automatic horizontal lifting clamps

have been designed for lifting and transferring

steel plates, beams and pipe lifting clamps in a secure and safe manner.

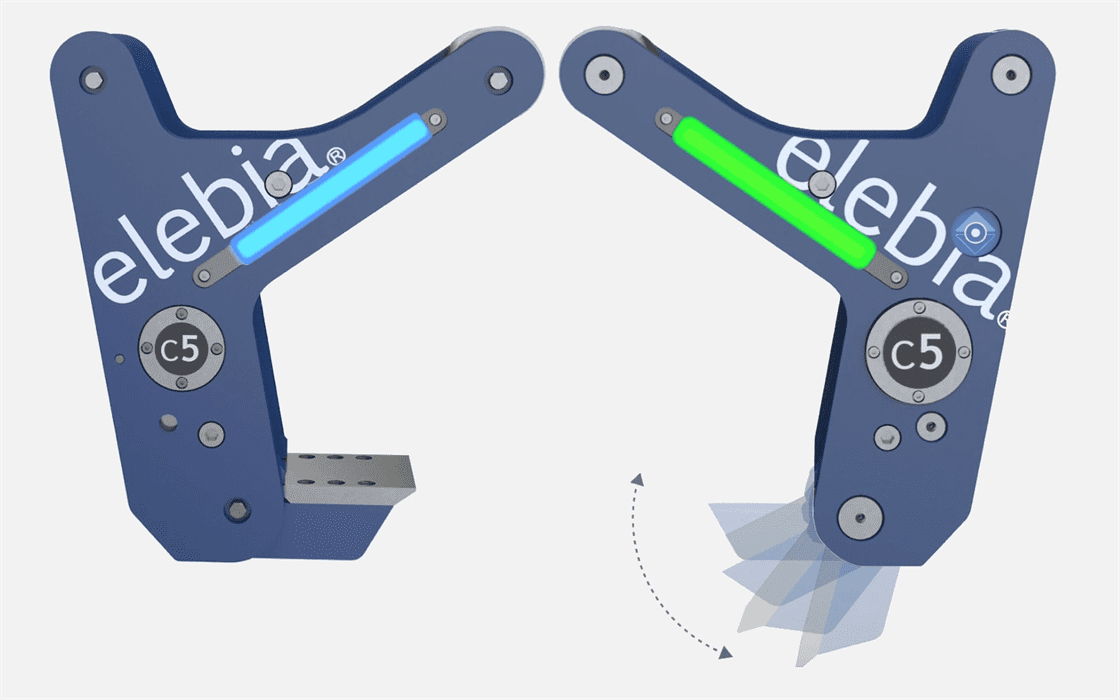

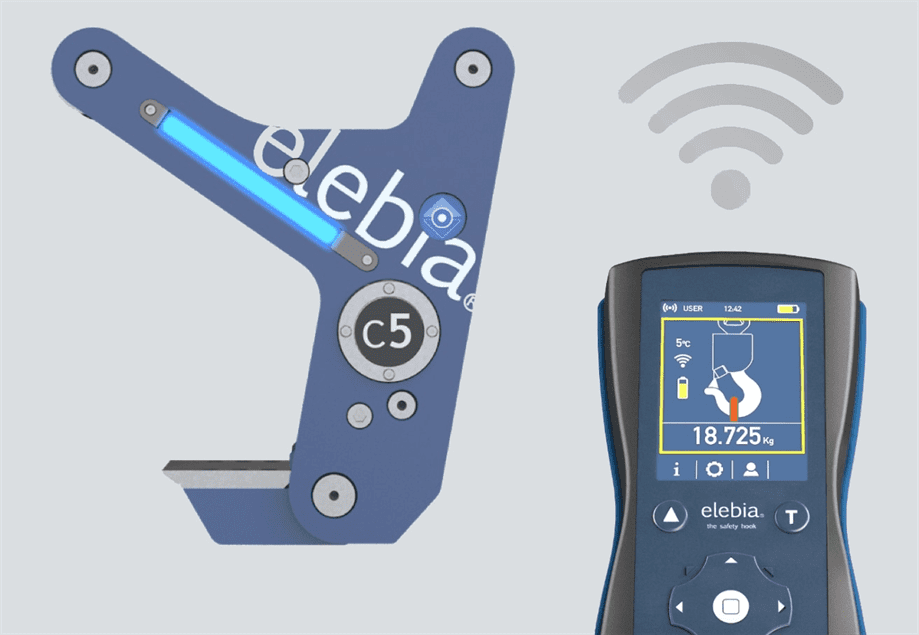

Locked/Unlocked Status for Automatic Locking Clamps

Once the automatic clamps are fixed to the load that is being lifted,

the automated process takes over. The crane driver/operator

ensures by using the eMAX remote control that the lifting clamps

are all in the same position before every lift.

This information is relayed in real time and should there be any difference in the

clamp’s states, the remote control informs the crane operator immediately.

Once all clamps are confirmed ready, the lifting operation can commence.

Locked Unlocked

LED Status Indicator for Safe Operations

The High-Brightness LED status indicator is an additional safety measure

that indicates the Lifting Clamp’s status at all times. With this feature operators

receive visual confirmation that the automatic release clamp is working properly.

Green: Unlocked / Release Load

Red: Intermediate: Do Not Lift!

Blue: Locked / Lift Load

White: Low Battery

Ergonomic & Simple to Use

The C5 & C6 automatic release clamps include a roller for chains or slings

and a hand grip that can also be used as a second lifting point. The hand grip allows the

operator to manually maneuver the clamp whilst fixing it on the desired surface.

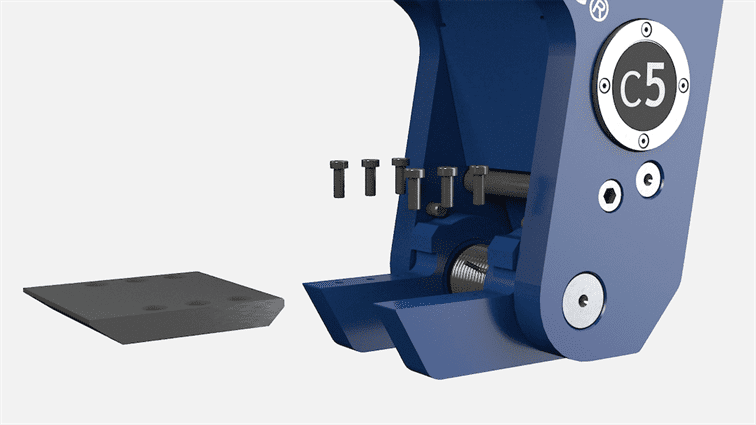

Change and Replace Heavy Duty Lifting Clamps

Easy to replace weared parts and to change the tip if to be used as a

Pipe Lifting Clamp, a Beam Lifting Clamp or a Plate Lifting Clamp.

See them in Action! Lifting Steel Plates and More

Safety Tests with Lifting Claws and Steel Plates

Release Comparison

Steel Pipes Lifting

See more examples here

Automatic Release Feature of Clamp for Lifting Metal

More than Efficient: Heavy Duty Lifting Clamps

With the high-capacity battery, a simple 3 hour charge allows

for more than 5.000 cycles or over 250 hours in standby mode.

The new 14 segment E-ink charge status display along with new

electronics and rechargeable Li-Ion technology guarantee an

optimal autonomy and consumption of the battery.

Charge the batteries with the Multiple Charger that’s compatible

with the C5 and C6 lifting clamps’ batteries. The Multiple Charger

can charge up to ten batteries simultaneously.

Remote Controlled

Open and close the C5 & C6 clamps or receive real-time information of weight,

battery level, and other values of the lifting and manoeuvring operation.

Just like the rest of our lifting products,

the automatic lifting clamps can be paired to any of our remote controls.

Fail-safe Design

Impossible to release the load while it is placed on the lifting clamp with automatic release.

Just like the complete range of our lifting products, the automatic release lifting clamps are

designed under a fail-safe principle that makes it impossible to drop a suspended load.

Regulatory Standards for Lifting Plate Clamps

The C5 & C6 lifting clamps certify with the following regulatory standards:

| ASME B30.10-2009 (C5) | UNE-EN 60204-1:2007 | D89/391/EEC |

| ASME B30.20-2010 (C5) | UNE-EN 61000-6-4:2007 | D89/654/EEC |

| UNE-EN 1050 | UNE-EN 61000-6-2:2006 | D89/655/EEC |

| UNE-EN 13155: 2021 (C6) | UNE-EN ISO12100:2012 | D89/656/EEC |

| EN 10204 3.1.B | D92/58/EEC 9a |

Directive on Machine Safety (D2006/42/EC).

EMC Directive (2014/30/EU).

Low Voltage Directive (2014/35/EU).

Radio Equipment Directive (2014/53/EU).

Assurance of Production Quality in accordance with ISO9001.

ARIB Construction Design Certification Number 203-JN0689.

FCC Identifier 2ACLHEVO for Equipment Class: Digital Transmission System.

Each mechanism is delivered with the CE stamp and a declaration of CE conformity.

elebia is a member of F.E.M. (European Federation of Materials Handling).

¡Check out our Crane Rail Lifting Clamps!

Applications

Ideal for lifting and transferring steel plates, beams or pipes in a secure and safe matter,

minimising risks, enhancing safety and increasing productivity in all your lifting operations.

Pipe Lifting Clamp

For horizontal lifting and moving of steel and concrete pipes. Thanks to the automatic release feature, the unloading operation is twice as fast, improving productivity. The pipe lifting clamp must always be used in pairs. The Working Load Limit indicated is per lifting clamp.

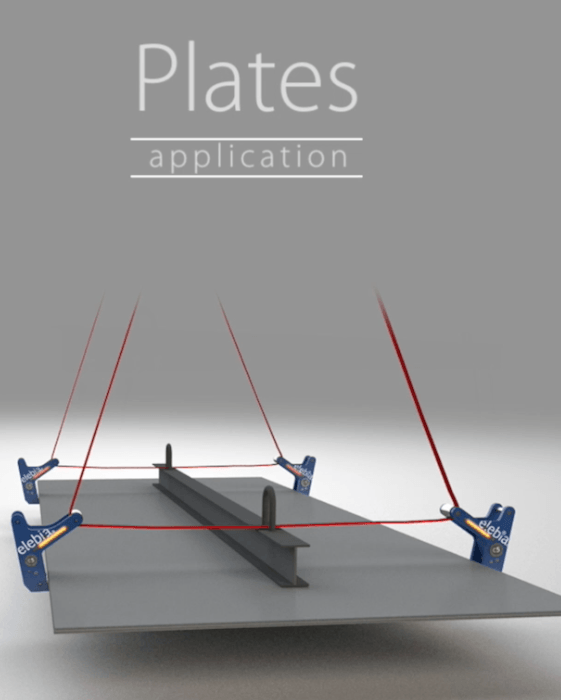

Plate Lifting Clamp

For horizontal lifting and moving of steel plates. The clamp’s flat tip effectively inserts into small clearances, securing the load before each lift. This plate lifting clamp must always be used in pairs (or multiples). The Working Load Limit indicated is per lifting clamp.

Beam Lifting Clamp

For horizontal lifting and transportation of steel (H) beams. Replace the tip with tip for beams to lift beams safely and securely. The beam lifting clamp must always be used in pairs. The Working Load Limit indicated is per lifting clamp.

Quick Links to Lifting Clamps Information

Configurator for Custom Lifting Clamps

Personalize and

configure your C5 & C6

horizontal lifting clamps.

Schedule a Demo of Lifting Clamps

Want to see in person how

your company can benefit by

using the C5 & C6 clamps?

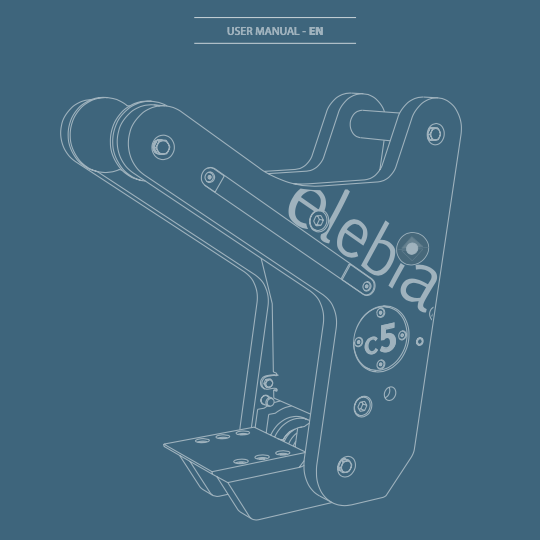

User Manual for Automatic Locking Clamps

All the info you need

and more, of the C5 & C6

horizontal lifting clamps.

FAQs Relevant to Lifting Clamps

What is the Working Load Limit of the elebia lifting clamps?

The C5 model has a WLL of 5,000 kgs (11,023 lbs) and the C6 model has a WLL of 6,000 kgs (13,227 lbs)

What are the different uses of lifting clamps?

A lifting clamp is a device used to position, hoist and move materials horizontally or vertically from one station to another. There are various styles and uses of lifting clamps on the market today to ensure that almost all the lifting and transport needs of any industry are met.

Can the same model of lifting clamp be used for different applications?

Yes. Both the C5 and the C6 lifting clamp can be used for different applications. All that is required is to change the tip of the clamp in order to adjust it for its intended use.

How does a sheet metal lifting clamp work?

Sheet metal lifting clamps work by securing a grip on the metal sheet, enabling a safe lift without slippage. The clamp typically locks onto the sheet’s edge, providing stability during lifting. Normally, two clamps are used in tandem to secure each end of the load, ensuring balanced lifting.

Are there lifting clamps specifically for lifting steel plates?

Yes, there are lifting clamps designed specifically for steel plates, ensuring safe handling and preventing damage to the metal surface.

What are the advantages of using horizontal lifting clamps?

Horizontal lifting clamps are ideal for stabilizing loads that need to be lifted parallel to the ground. They distribute weight evenly and reduce the risk of tilting.

How do automatic locking clamps enhance safety during lifting?

Horizontal lifting clamps are ideal for stabilizing loads that need to be lifted parallel to the ground. They distribute weight evenly and reduce the risk of tilting.