Choosing The Right Hook

25 February, 2022 - Editorial Team

Sometimes, the decision of choosing the right hook for the task at hand can not be made easily. It is not enough to only take into account the load capacity of the products that are to be lifted. There are other factors that must be taken into account which influence the optimal lifting process of products, and therefore, the ideal engage, transport and release of the load.

Choosing the right hook

1. Lifting capacity of the hook and its lifting accessories

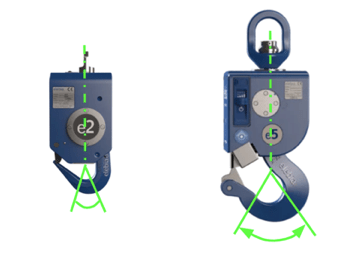

Our products have to compete with other hooks, but because the Elebia lifting hooks carry mechanisms, sensors, etc…, they tend to be heavier and more bulky. In our quest to make them as compact and as light as possible, during the design process, we bear in mind the most common accessories that they will work with in order to optimize their geometry.

Therefore, it is necessary to confirm the size and geometry of the lifting accessories (shackles, chains, rings…) used by the end customer in order to choose the right hook. On certain occasions though, it will be the customer who will have to adapt or modify their lifting accessories.

For example, a 5Tn ring may be suitable for a standard 2,5Tn hook, but not for the evo2 crane hook. In this scenario, either the lifting accessories are adapted for the evo2 crane hook or the best option is to choose the evo5 hook, with a higher lifting capacity. Learn about our entire range of automatic crane hooks.

Newsletter

Sign up for our newsletter and get the latest news from elebia

2. Application – Work Procedures

There are many different types of lifting procedures. Of the different types, there are some that are highly standardized and where cargo handling is the same all over the world. And then there are others that are less standardized, meaning that the lifting procedure is handled differently by each company.

When we talk about standardized loads, it is easy to foresee that if a hook model works perfectly for one client, it will do so as well for another. However, when the load is not standardized, this does not have to be the case, and all the particularities of the lifting procedure must then be taken into consideration.

– Paper Pulp

A clear example of a standardized load is paper pulp. The bales are generally wrapped with extremely tight wires around them. The geometry of the tip of the evo2’s forged hook is very slim and small, as it was developed with this application in mind. For this reason, it can be easily inserted between the wires and the bale, allowing the easy engage and transport of the load. This operation would be impossible to perform with an evo5 due to the geometry of this model’s tip.

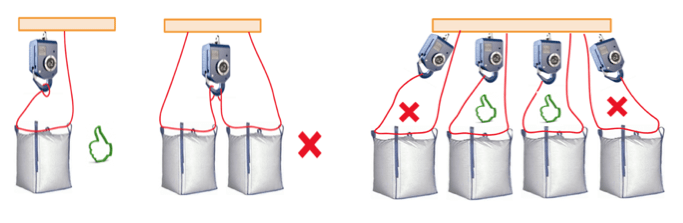

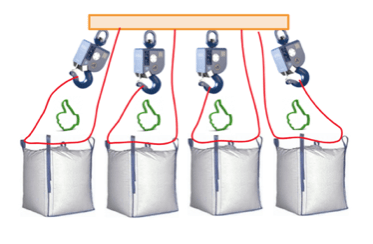

– Big Bags

The transport of big bags would be an example of non-standardized cargo. Big bags can be lifted directly from their handles, using a sling for each big bag, a single sling for several big bags, different types of slings, different length of slings, different anchor points of the slings, etc. Large slings can be more difficult to insert into the evo2, causing the load to sit on the tip of the forged hook, impairing its engage and transport.

The evo5 is a larger hook, making it easier to connect with the 4 corner handles of the big bags and with larger slings. Also, the shape of the forged hook helps the load to be placed in the center of the hook, avoiding lifting the load by the tip.

Here are some examples:

3) Nonoptimal conditions

There are many occasions where it cannot be ensured that the lifting process is carried out under optimal conditions and in a fully controlled environment. There are different external factors, depending on the application and the environment, that make it advisable to choose a lifting hook with a higher load capacity. Among them we can highlight the most common:

• Dynamic load

When loads move with high accelerations, forces appear on the lifting accessories that must be included in the total sum of the weight that is being lifted. If these forces are not correctly calculated, there is a chance the hooks may be overloaded. These accelerations can be due, for example, to rapid movements of the crane, and in offshore operations, to waves in the sea.

• Unbalanced load

If a load is lifted by more than one lifting point, and its center of gravity is not positioned correctly, the load on the hooks will not be equal, resulting in a possible overload of one (or more) of the hooks.

• Hyperstatic lifting

When a load is lifted by more than three lifting points. The distribution of the load between the lifting accessories does not necessarily end up being equal. It will depend on the rigidity of the structure, so it may be that one of the hooks is overloaded.

• Impacts

Due to, for example, the lack of precision of the crane, lack of visibility, adverse weather conditions, obstacles, incorrect use by operators, etc., the hooks can be subjected to impacts. These can damage non-structural components, affecting their operation. Higher capacity models tend to resist impacts better.

Products Made For Your Company