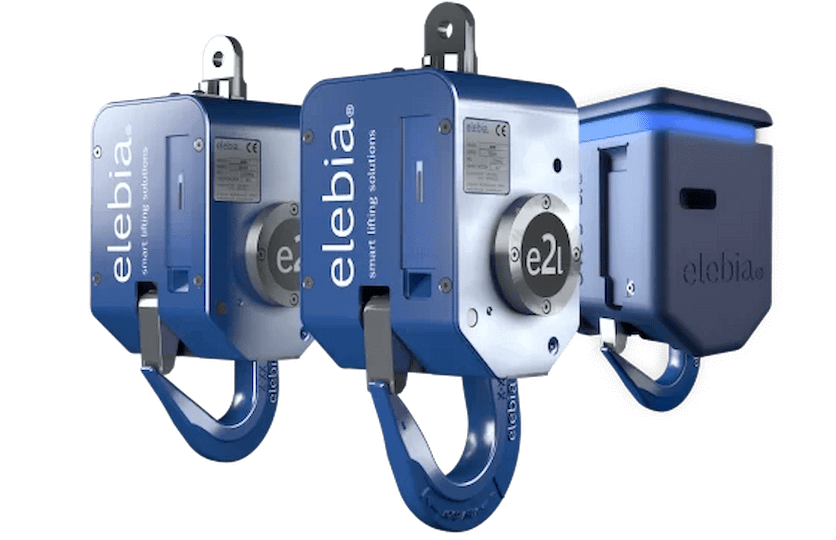

Automatic Crane Hooks from Elebia

Discover the innovative Elebia Automatic Crane Hooks. With the evo2 and evo5 ranges of automatic load hooks, Elebia has created a compact, lightweight, and highly efficient solution. These smart crane hooks allow for remote attachment and release of loads, enhancing safety and productivity in all your lifting operations. Experience a new era of ease and effectiveness in load handling with Elebia Automatic Crane Load Hooks.

Our Automatic Crane Loading Hooks

Intelligent

This cargo lashing hook contains a sensor in the magnet indicating when the ring is in position. All this information is recorded in the eMAX remote control, which acts as a HUB capturing all the information and registering all the activity of the industrial crane hook.

Efficient

We have redesigned the high-capacity battery to improve its lifespan during each charge and thus reduce the energy consumption of the hoist hook for elevators. It charges in three hours and allows up to 5,000 cycles or 250 hours on standby.

Powerful

The new motor of the cargo lashing hook allows releasing up to 20 kgs of load so there will be no more problems releasing heavy slings. Thanks to the automatic release feature, the load release limit can be adjusted, protected by a safety latch so that overloads or impacts do not damage the motor.

Resistant

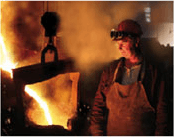

Electric hook designed to work in the toughest conditions (steel mills, ports, extreme temperatures) and manufactured with the best materials. Industrial crane hook forged type T or V, with WELDOX high-strength steel body.

Benefits of Automatic vs. Manual Crane Hooks

Greater safety: Automatic cargo lashing hooks ensure a secure and reliable attachment of the load, avoiding potential human errors in the process. This reduces the risk of accidents and injuries during lifting operations.

- In high-altitude operations, the risk of fatal accidents is eliminated.

- Reduction of injuries and chronic ailments by eliminating displacements and repetitive movements, such as climbing on and off the truck.

- The risk of hand injuries (cuts, crushes, etc.) is eliminated by not having to touch slings or other lifting accessories.

- When handling toxic loads, operator contact with them is avoided.

Greater comfort and convenience: Operators no longer need to perform physically demanding tasks, such as climbing onto the crane or using manual tools to hook the load thanks to the Elebia automatic system. Nowadays, it is possible to remotely attach and detach any load using any of the Elebia remote controls.

- The user experiences increased comfort in the workplace. The effort required in carrying out various operations is reduced thanks to the safety crane hooks.

- Working conditions improve, along with productivity and safety.

Versatility and adaptability: Designed to adapt to a wide range of applications and types of cargo. Some models even offer specific attachment options, such as master rings or slings.

Efficiency and precision: Thanks to their automated operation, Elebia automatic hooks offer greater precision and control during lifting operations. This minimises the risk of damage to the load, optimises resource usage, and improves overall work efficiency.

Check out more about the different Types of Hooks and our Lifting Hooks.

We show you how our rotating crane hook works

Loading and Unloading

Handling and transportation

Unique Lifting Point

Global solutions with our automatic hook

<

Industrial Loading Hooks for Remote Control Crane

Automatic Crane Hooks for Loads in Special Environments

Marine Environment

C5M paint and AISI components.

Recommended for:

Marine Environments

Industries:

Offshore Wind Turbines, Onboard Cranes, Buoys

DNV Certification

The evo5, evo10 and evo20 automatic cargo lashing hooks comply with current regulations: Standard for onboard lifting devices (DNVGL-ST-0377) and Standard for offshore lifting devices and platforms (DNVGL-ST-0378)

Recommended for:

Offshore Operations.

Industries:

Offshore Wind Turbines, Onboard Cranes

ATEX/IECEx

Units with IECEx certification for zones 1 and 21 in accordance with European Directive 2014/34/EU and international IECEx standards.

IECEx certification to work in areas classified as zone 1 and 21 in accordance with European Directive 99/92/EC and international IECEx standards.

Comparatively, ATEX/IECEx and North American NEC 500/505 classification, units comply with NEC Class 1 Division 1.

Recommended for:

Applications with potentially explosive environments.

Industries:

Oil & Gas, Mining and Chemicals.

Thermal Protector

Thermal protector that protects the automatic hook and its electronic components from radiated heat and a range of extreme temperatures.

Recommended for:

Applications where the hook receives a lot of radiated heat.

Industries:

Foundries.

FAQs about our Automatic Hook Cranes

Is it possible to open the hook with the load suspended?

Thanks to its “fail-safe” design, the hook is not capable of opening and dropping the load*. It is a secure, fail-safe design. Gravity is what keeps the hook closed in position. The electric motor does not have enough power to rotate the hook. (*) It does allow slinging accessories to be detached, whose weight is below 20 kg. (44.09 lbs.)

Can the elebia automatic hook be controlled by the crane remote control?

Yes. To do this, you must purchase the installable remote control. This will allow the automatic hook to be controlled using the crane controls (the crane control must have a free channel, with its button and relay). This system is universal, that is, it is compatible with all remote control manufacturers.

Can you control multiple hooks with the same remote control?

Indeed. The eMAX remote control allows you to simultaneously control up to 24 automatic hooks.

Is the elebia system valid for all types of cranes?

Yes it is. The elebia automatic hook works with removable and rechargeable batteries and radio control. It does not require any installation.

Do snap hooks attract each other due to the effect of their magnetic fields?

No. The intensity of magnetic fields decreases rapidly with distance. Therefore, despite the power of the magnets, at about 25 cm. From a distance the field is barely perceptible.

Can the equipment be wired?

Yes. We can deliver the wired automatic hooks. We can wire the power for 24V DC. With this you can do without batteries. You can also wire the input and output signals. In cases where power and/or signals are wired, the rotary is locked to avoid possible wiring entanglements.

Batteries

What is the battery life?

The life of the product depends on use, care and maintenance. If the recommended conditions of use are respected (temperature, humidity, etc.), a battery can last up to two years.

What is the battery charging time?

Less than 3 hours for a full charge.

Should the battery be fully charged and discharged to extend its life?

Lithium-ion batteries do not have the memory effect, so full charging/discharging is not necessary.

Can lithium ion batteries be stored for long periods of time?

Lithium-ion batteries should not be stored for a long time, as they age and lose their capacity. If it is necessary to store them for long periods of time, it is recommended to charge them up to 50% of their capacity, and recharge them every 3 months. A good solution is to have a second spare battery, to use them alternatively (while one is used, the other is charged).

More information about batteries here.

Maintenance and Warranty

What is the hook maintenance procedure?

As loading equipment, it must be visually inspected to verify that there are no cracks or deformations. It is our recommendation that elebia technical service perform a complete review at least once a year or every 100,000 use cycles.

What are the most common breakdowns or breakages?

The safety trigger is a fungible element, and it can frequently break or deteriorate due to its own use. In case of severe impacts, the motor and electronics may be damaged.

What is the warranty on elebia products?

All elebia products have a 2-year warranty period except for batteries, whose period is 6 months.

Others

How can you benefit from the automatic crane hook in big bag applications?

The automatic load hook for crane makes it easy to anchor said load remotely and generates a magnetic field that attracts, centers and orients the ring or sling. In this way, the operator only has to press a button on the remote control to automatically close the lifting hook, operating as remote and maintaining its security.

What does the magnetic system of Elebia electric crane lifting hooks consist of?

Elebia automatic sling hooks are made up of a magnetic system unique with 32 permanent neodymium magnets positioned in a specific configuration to generate a magnetic field oriented that performs three functions: attracting, centering and directing the ring and that allows the attachment of loads from a distance thanks to a remote control.

Are automatic crane loading hooks not damaged by daily use?

Product life can be extended by using bumpers. They protect the lifting hook (and operators) from impacts, reduce maintenance costs and increase overall safety in any lifting operation.

What materials are used in the production of crane lifting hooks?

Generally, crane automatic sling hooks are made of iron or steel. Some common materials used include carbon steel, alloy steels, wrought iron, HSLA, chrome steel, stainless steel, and cast iron.

Are safety latches required on automatic crane lifting hooks?

When deciding whether to use a safety latch or not, special attention should be paid to the specific lifting application. At Elebia, our automatic crane hooks can carry one of two options: a spring-loaded latch or a rigid safety latch.

What is the lifting capacity of the evo range of automatic industrial crane hooks?

The range of the automatic hooks for evo slings range from 2.5 tons of lifting hook capacity of the evo2 crane up to 25 tons and allow any load to be hooked and released remotely.