Monorail Crane: What is it, Types and Benefits

4 October, 2019 - Editorial Team

An industrial working station requires a lot of lifting and moving bulk materials from different stations in the factory. Relying on human labour for such a task can be expensive, time-consuming and dangerous, hence the reason why most industries have introduced overhead cranes systems to do the job. Overhead cranes are essential in various sectors as they make work more efficient, but the effectiveness is also determined by the crane design.

What is a Monorail Crane?

A monorail crane is a type of crane that acts as a substitute for conventional cranes and conveyor belts. These cranes are mostly used to relocate materials or products within a restricted area. Such sites could be a factory or throughout the working station. Monorail crane design is simpler and can be compatible with the structure of the building without major changes.

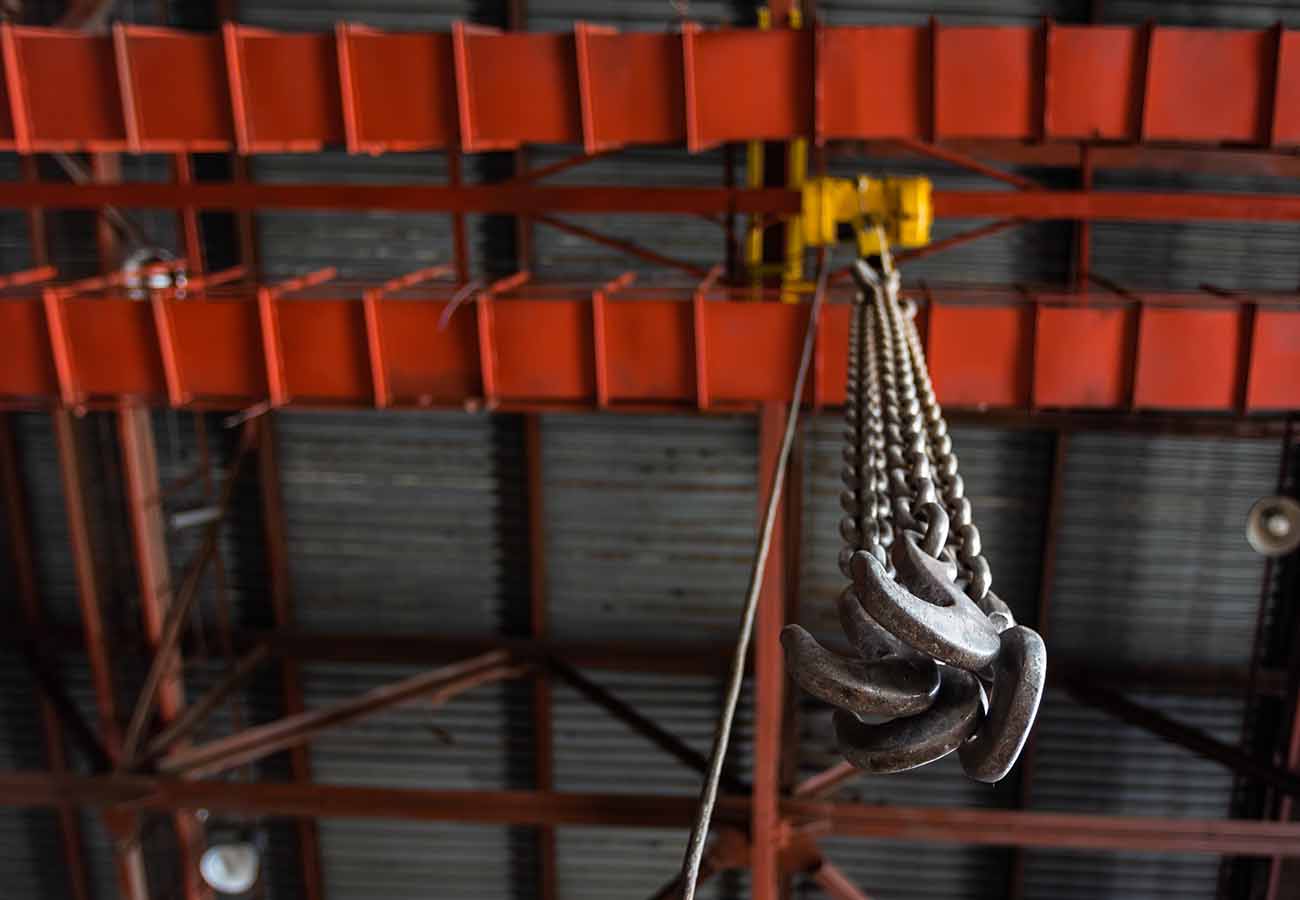

The cranes can enter into the building or factory via the ceiling columns or added monorail beam to support the metal trolley. The cart can run on the beam or hang below depending on the building’s ceiling elevation and the required lifting capability. A monorail crane hoist is attached on the trolley using a steel cable or chain for lifting, lowering and suspending the load to the designated location.

Types of Monorail Overhead Cranes

There are a few types of monorail cranes available in the market. Some only run on a straight line from one end of a room to another while others can move through curved beam designs to improve flexibility. Another way to classify monorail systems is by the used operating systems. Some of the cranes are manual while others are electrical — using electrical motors to run. Some of the monorail systems are also automated, meaning operators can use remote controls and other modern systems.

- Patented track monorails: these monorails have a track that is fabricated to resemble an inverted letter T. The T section acts as the flange for the trolley’s running wheels.

- Enclosed track monorails: these monorail systems have a rectangular track with a continuous track fabricated on the lengths of the underside. The trolley uses a flange to travel along the track.

Benefits of Monorail Cranes

Although there are various types of monorail cranes, they all share the same benefits:

Flexible

Monorail cranes are useful in a variety of facilities, unlike other cranes that can only work outdoors. The cranes’ systems are also easy to modify in case of expansion requirements or changes to fit the business space available.

Fast

Monorail cranes can move loads around the production floor from point A to point B in the most efficient way. They are also above most obstacles, hence avoiding long routes used when navigating the obstacles.

Easy Control

Modern systems allow users to control monorail cranes through simple automated systems. The operator will be at a single location where he has clear visibility of the path followed by the load for easier control.

Customisable

Monorail cranes are easy to customise according to the features of a production line. They can move through curves, slopes outdoors and even between different works stations. Users can also add other features such as below the hook attachments and other specialised tools to help in handling a variety of loads.

Newsletter

Sign up for our newsletter and get the latest news from elebia

Lifting Hooks

A good example of such in monorail hoist systems customisation includes the elebia hooks. Our hooks come with additional efficiency and safety features like:

- Remote attach and release of any load, hence avoiding a lot of human handling and moving to minimise risks, enhance safety and improve productivity.

- The hooks have load cells to weigh the load when lifting. Such an improvement helps avoid overloads for safety and machine durability benefits. It is also possible to configure the crane hook with an alarm that activates itself in case someone exceeds the hook’s load capacity.

- Fail-safe design: the evo range of crane hooks also enhance safety through fail-safe principles. The fail-safe design uses geometry to ensure that the automatic hook cannot drop the suspended load.

- Increase in productivity: the improved safety features improve worker’s confidence knowing they can work faster with no risk of injury.

In short, we can say that cranes are valuable equipment in any work set up involving the transfer of heavy products and loads. The market offers a variety of crane types and design systems, and it is up to the user to choose the one that fits their need. Monorail cranes are a good choice for an indoor production line involving the frequent movement of materials and products from one point to another within the work station.