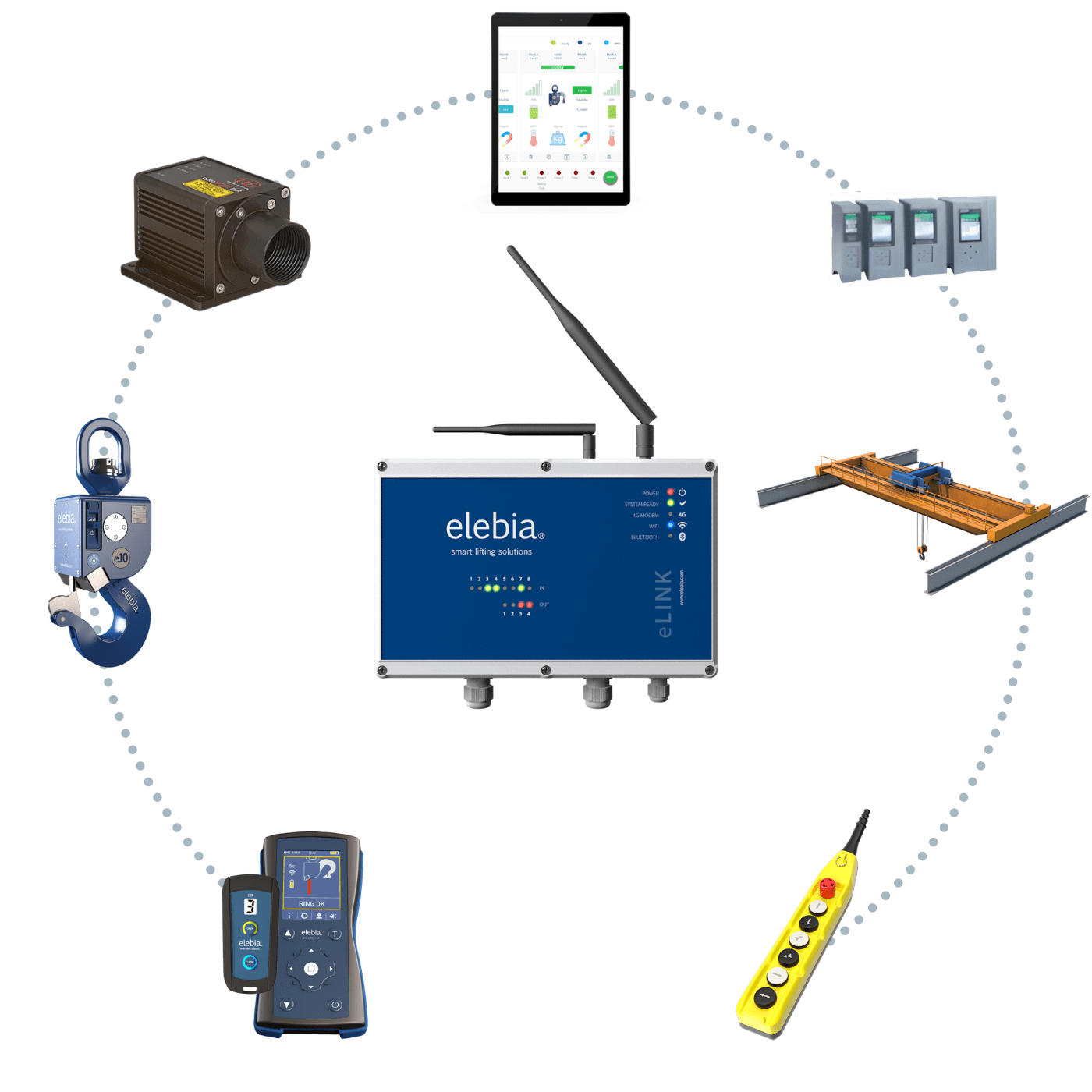

Functions of the eLINK

eLINK: Central Data Acquisition and Control System

Single Board Computer (SBC)

Central data acquisition and control system

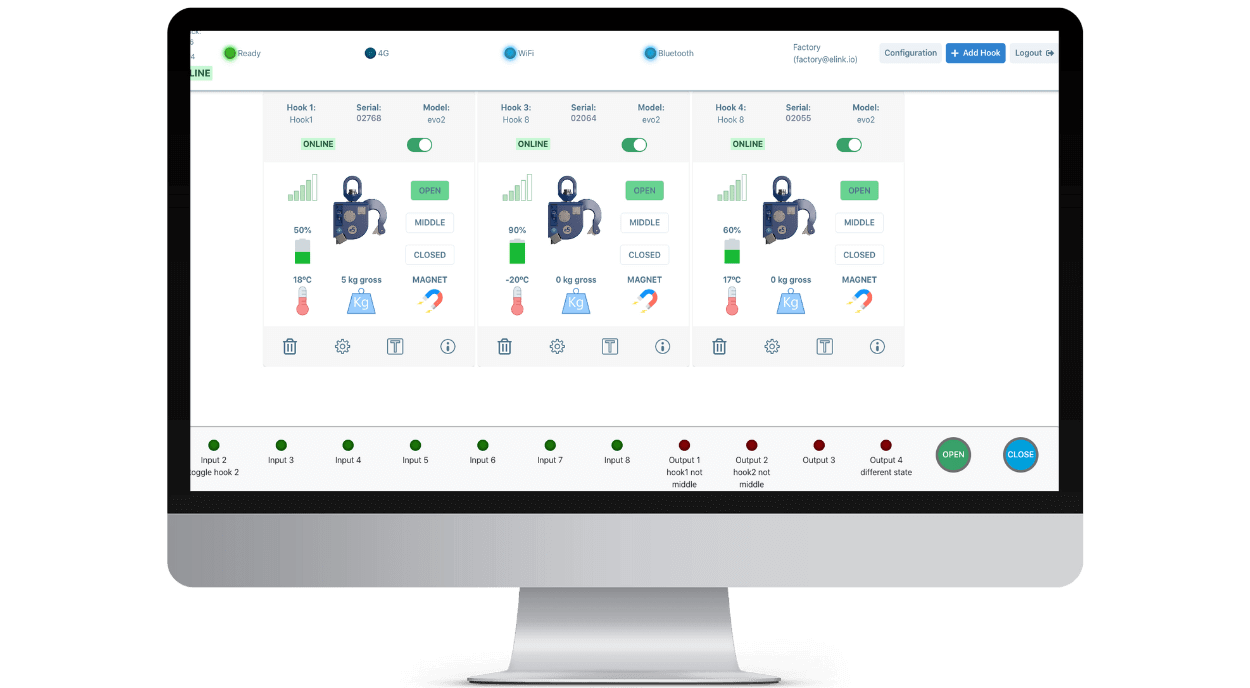

Communicates with the user through a web application interface

Allows the user to view and control the status of the different lifting hooks

It is installed in the electrical panel of the crane.

With Wifi, bluetooth, CANbus communication and the possibility of connecting a 4G module (both optional)

Benefits of the eLINK

Safety

The Elink will only allow the load to be lifted if the safety conditions are met.

Automation

Crane and hook automation

Servicing

![]()

Monitoring, diagnostics, support, service, preventive maintenance

Data log/Monitoring

![]()

Event log, data analysis, productivity metrics.

How Does it Work?

Select one of the elements to see its function.

Communication with the user

Using a web application connected to any mobile device, be it PC, tablet and/or smartphone

Compatible with Windows, MacOS, iOS & Android Operating Systems.

· eLINK serves a Web App

· users can connect using Wi-Fi, Bluetooth, 4G

· local or global access

· user & password login

· different profiles/access levels (user, admin, service, factory)

Communication with Elebia lifting hooks

Via radio communication

The eLINK gives and receives all the info from the

hooks, and has full control of the hooks.

(orders and set up parameters, etc...)

Elebia Remote Control

Elebia Remote Control

The automatic lifting hooks can be controlled using either the eMAX or eMINI remote controls (one or many).

Remote Control

Crane Remote Control

The automatic lifting hooks can also be controlled using the crane's OEM controls, either remote or pendant.

Communication with the crane's elements

Crane control by CANbus or 4 output dry contacts

User defined logical rules, using the hook's sensor information, can be used to automate hooks and crane behaviour.

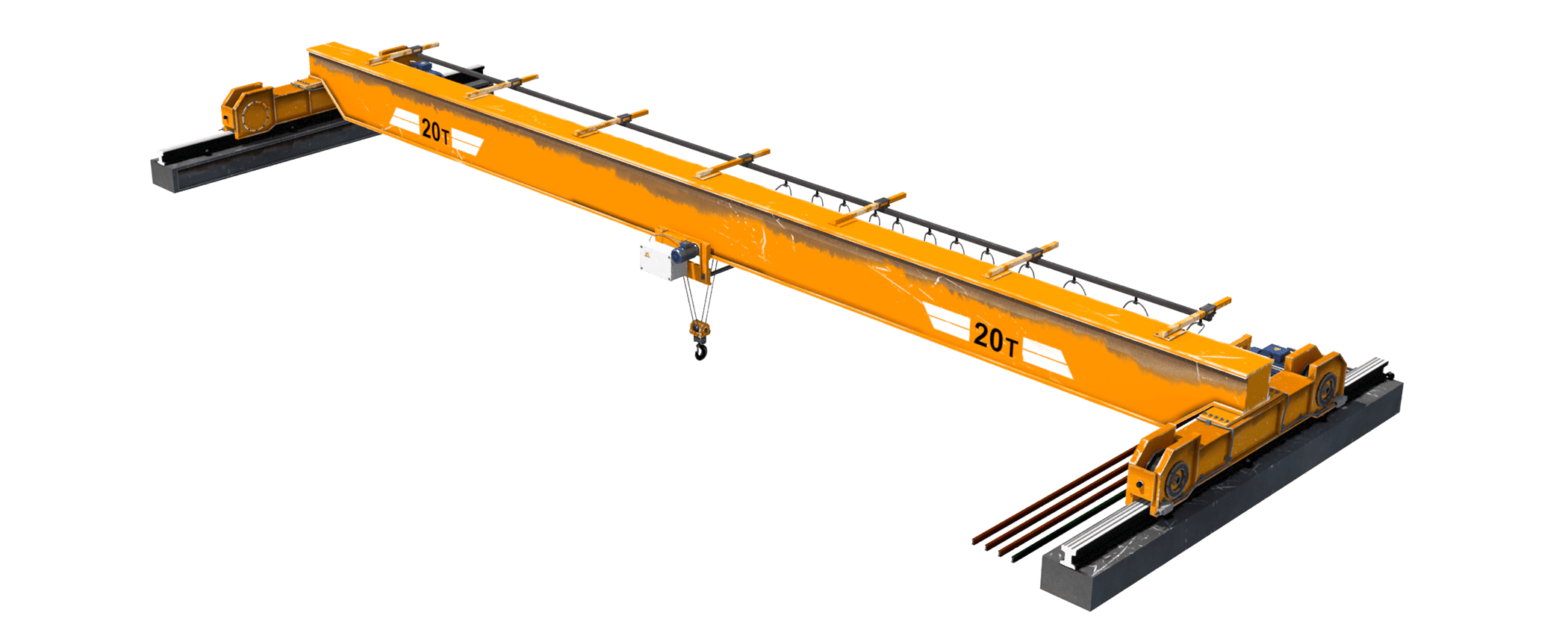

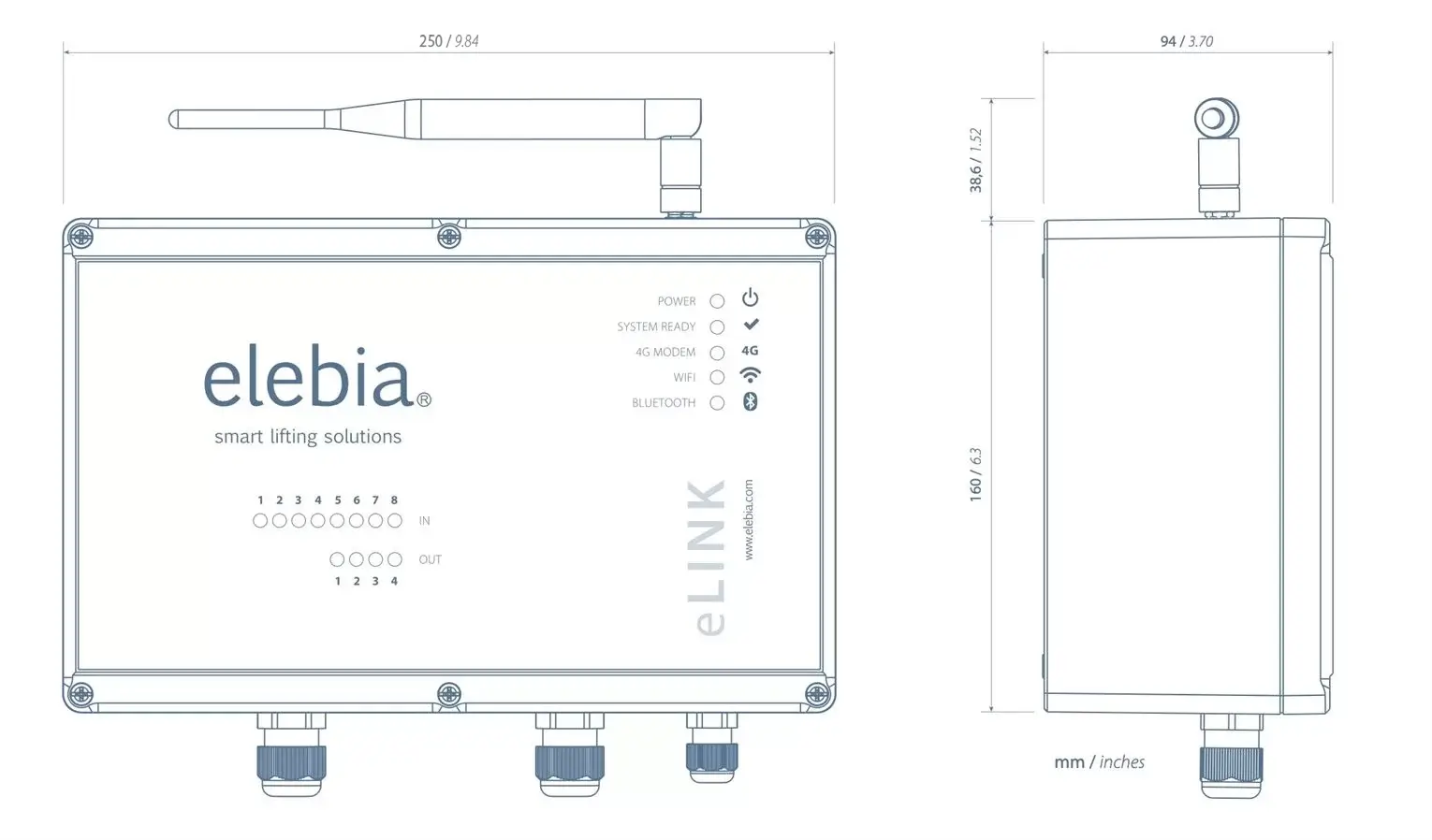

The eLINK

Central Data Acquisition and Control System

The eLINK is a central control and data acquisition system that has three communication channels: with the user through a web application connected to any mobile device, be it PC, tablet and/or smartphone; with the elements of the crane through 8 input channels and 4 output channels; and with the lifting hooks through radio communication.

laser sensors

lights, buzzers, screens,...

PLC'c

In Detail

eLINK Specifications

| Single-Board Computer | _____ | Cortex-A17 Quad-core SoC* |

| Radio Frequency Communication | _____ | 868.95 / 904 / 917.5 / 924.1 MHz |

| CANbus | _____ | Optional |

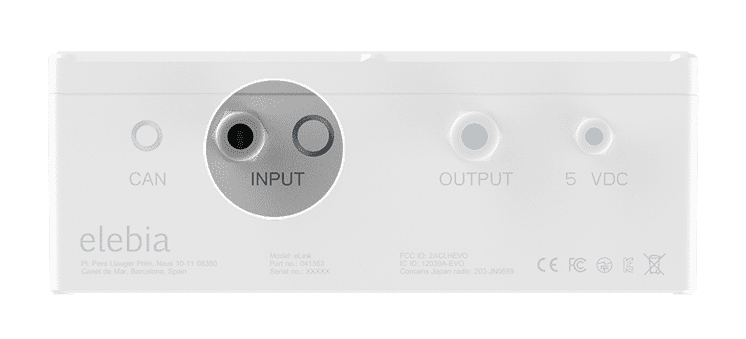

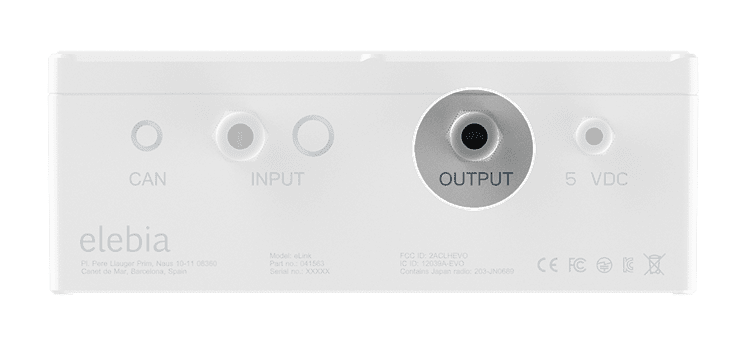

| Inputs | _____ | 8 dry contacts |

| Outputs | _____ | 4 relay contacts. Max 1A |

| 4G Module | _____ | Optional |

| Real Time Clock (RTC) | _____ | Yes |

| Internal Storage Memory | _____ | 32GB |

| Battery Button for RTC | _____ | CR2032 |

| Input Source | _____ | 110/230Vac;48Vcc/24Vcc |

| Wi-fi | _____ | 802.11 b/g/n |

| Bluetooth | _____ | 4.2 +EDR |

| IP Code | _____ | IP65 |

| Temperature Range | _____ | -20ºC to 60ºC |

| RF Antenna | _____ | 862 to 930 MHz / 50 Ohms |

![]()

Central Data Acquisition and Control System

The eLINK is a central control and data acquisition system that has three communication channels:

- with the user through a web application connected to any mobile device, be it PC, tablet and/or smartphone

- with the elements of the crane through 8 input channels and 4 output channels

- with the lifting hooks through radio communication.

It is installed in the crane panel itself, with which we can directly make the appropriate connections of the crane elements that we want to control (such as the Interlock), using the 8 inputs and 4 outputs controlled by relay.

The main operating function is the control of the lifting hooks, either individually or in groups, through the web application. This allows the user to perform different logical functions through the inputs and outputs that are connected to the eLINK, in order to improve the control of the different scenarios that need to be managed. The device itself generates a Log file which informs of all the events that are carried out while the eLink is operating, saving each event with date and timestamp thanks to the Real Time Clock that the device carries.

Communication with User

Select the element of the image you wish to identify.

Radio strenght

Battery level

Temperature

Weight

magnet sensor

Hook status

Hook settings

Hook info center

Tare/ Gross/ New weight

Relay status

Input status

Radio strenght

Radio strenght

Hook status

Hook status

Battery level

Battery level

Weight

Weight

Temperature

Temperature

magnet sensor

magnet sensor

Hook info center

Hook info center

Tare/ Gross/ New weight

Tare/ Gross/ New weight

Hook settings

Hook settings

- eLINK serves a Web App

- local or global access

- user & password login

- different profiles/access levels

- local or global access

- local connection wifi (tru bluetooth)

- remote connection : Internet or 4G (optional)

- compatible with Windows, MacOS, iOS & Android

allows to control Hooks:

link hooks

set up hooks

access hook status

access hook log files

control hooks (open/close)

allows to control eLINK:

set up eLINK

set up logical rules

set up relays

set up inputs

Communication with the Crane’s Elements

Crane control by CANbus or 4 output

User-defined logical rules, using the hook’s sensors information, can be used to automate crane behavior, enabling safer lifting with Elebia hooks.

examples: (amongst many other possibilities)

– if Hook #1 is not fully open/closed, then block the crane.

– if Hook #1 has an overload, then block the crane and sound the alarm.

– if Hook #1 and Hook #2 are not in the same state, then block the crane.

– if the temperature of hook #1 is >80ºC, then sound the alarm.