Current Situation in Offshore Operations

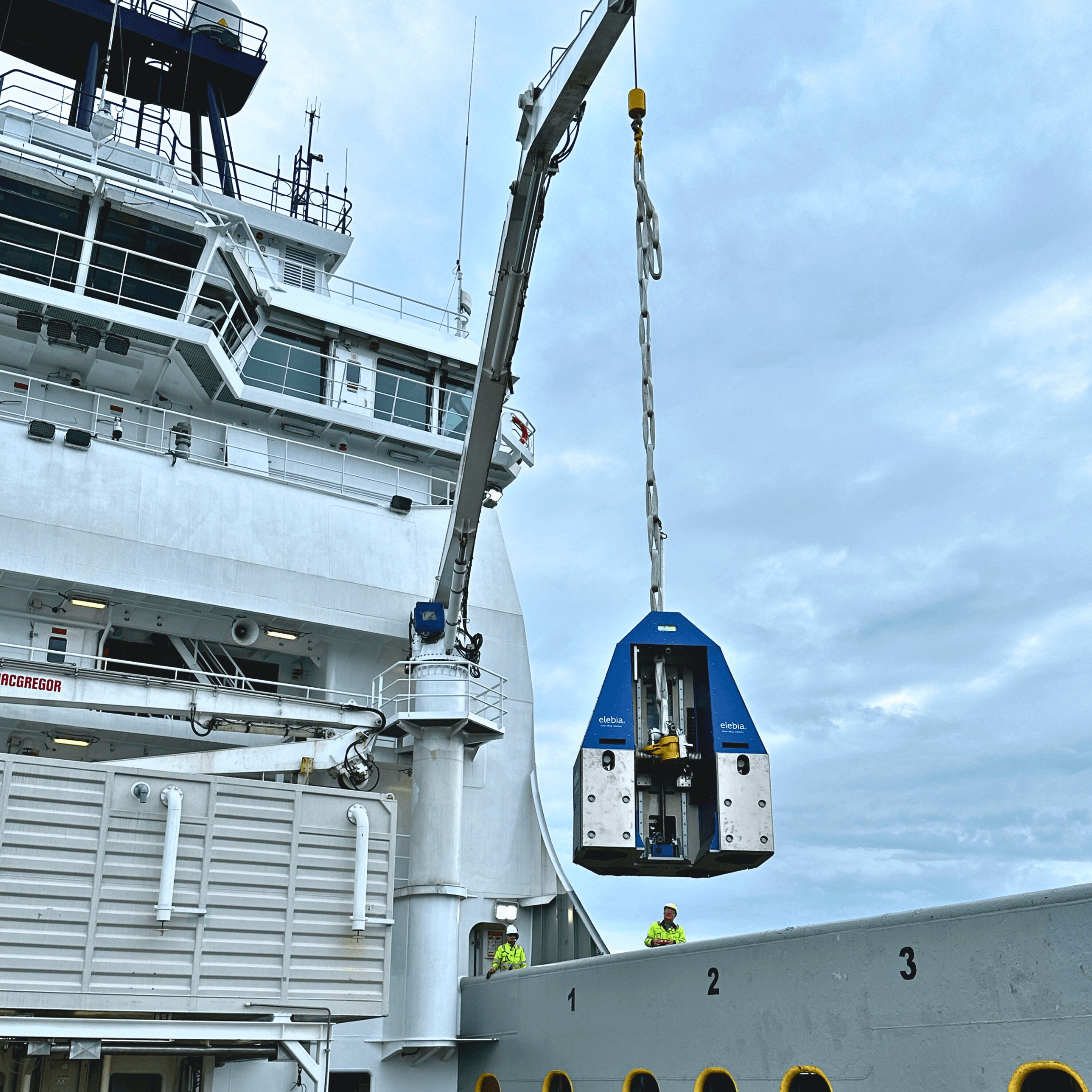

The Hookbot remote-controlled robot for offshore platforms has been designed with the goal to improve safety, minimise risks and incease productivity in handling and moving containers in maritime platforms and in extreme conditions.

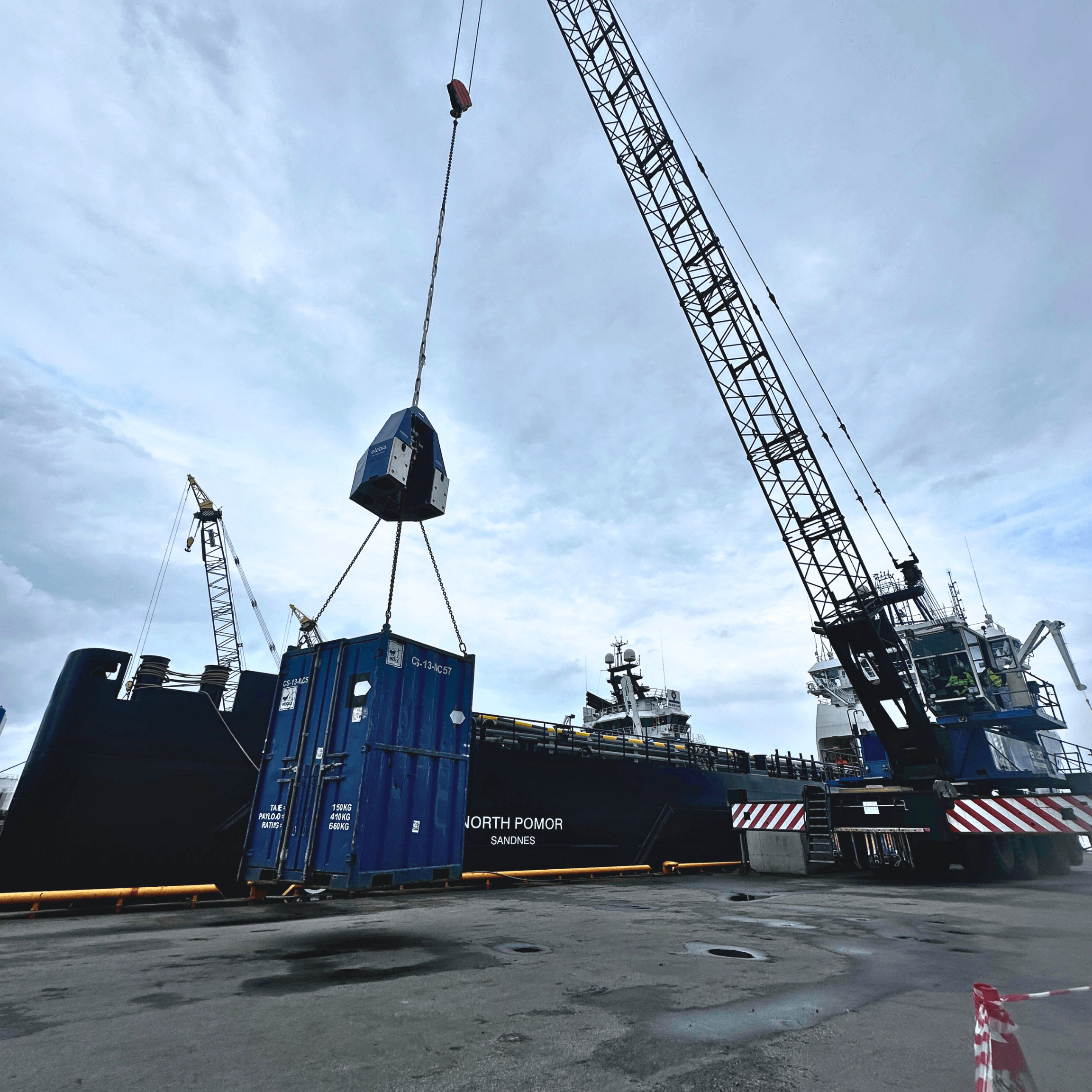

Currently, handling and moving this cargo carries intrinsic risks for operators who intervene when engaging and disengaging the lifting chains from the containers. Specifically, on oil platforms during the loading and unloading of containers from a supply ship.

The ship’s movement, along with the handling capacity of the crane operator, generate instability and insecurity due to the relative movement between platform and ship in the positioning of the containers.

This often causes impacts with other containers or metal structures of the cargo ship.

Close to 1/3 of incidents in offshore platforms are related to the lifting process.

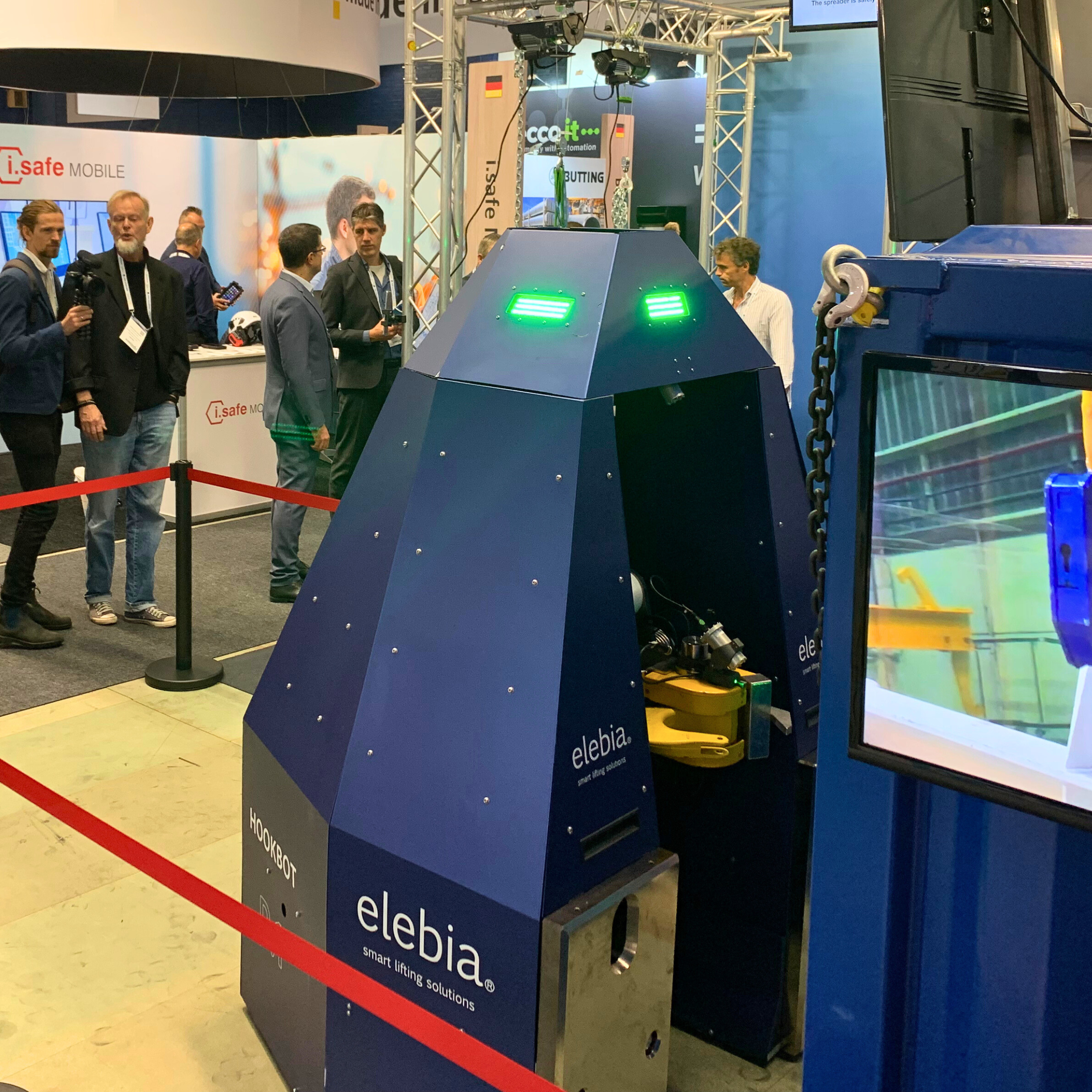

Explore the Features of the Hookbot for Offshore Platforms

See the First Prototype of the Hookbot in Action

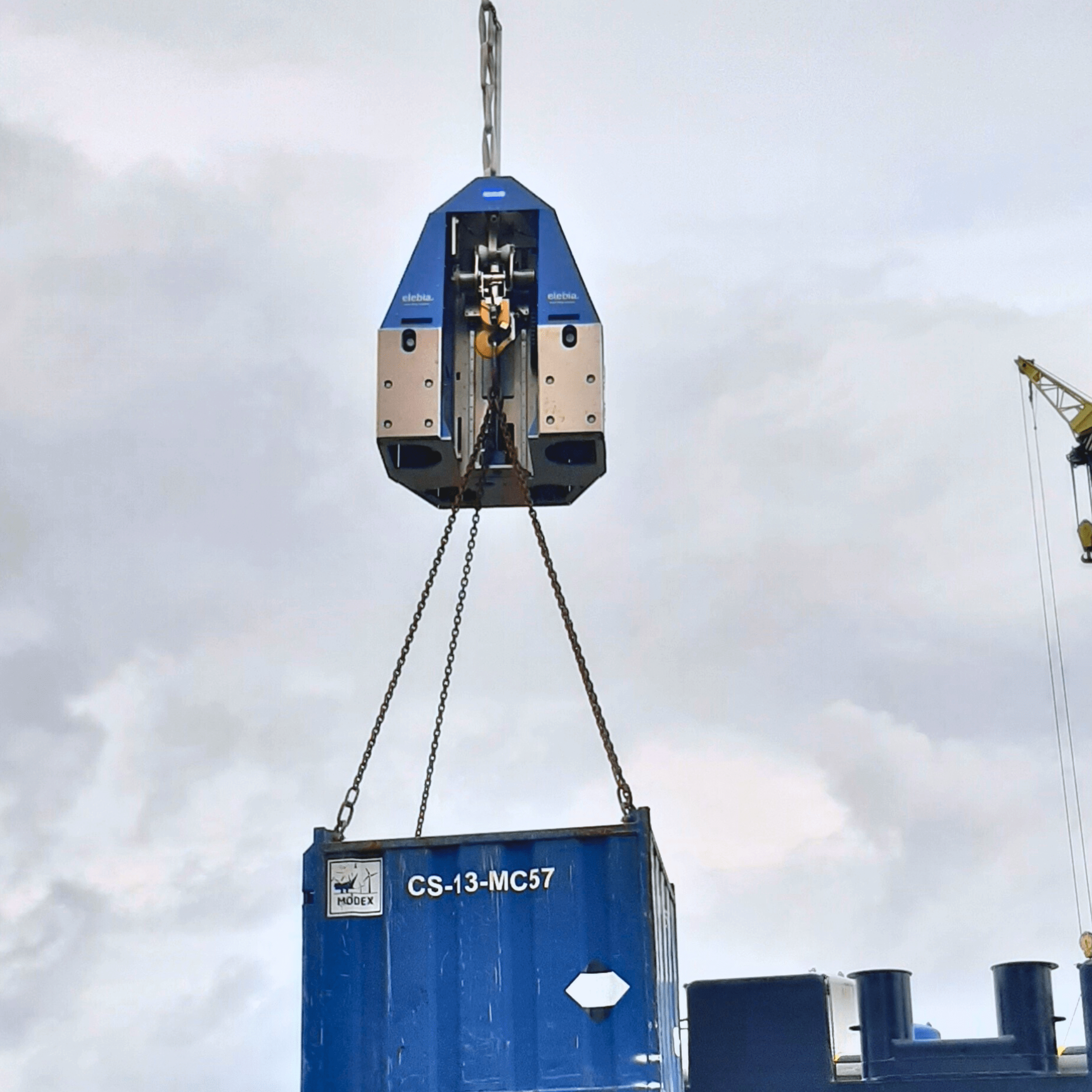

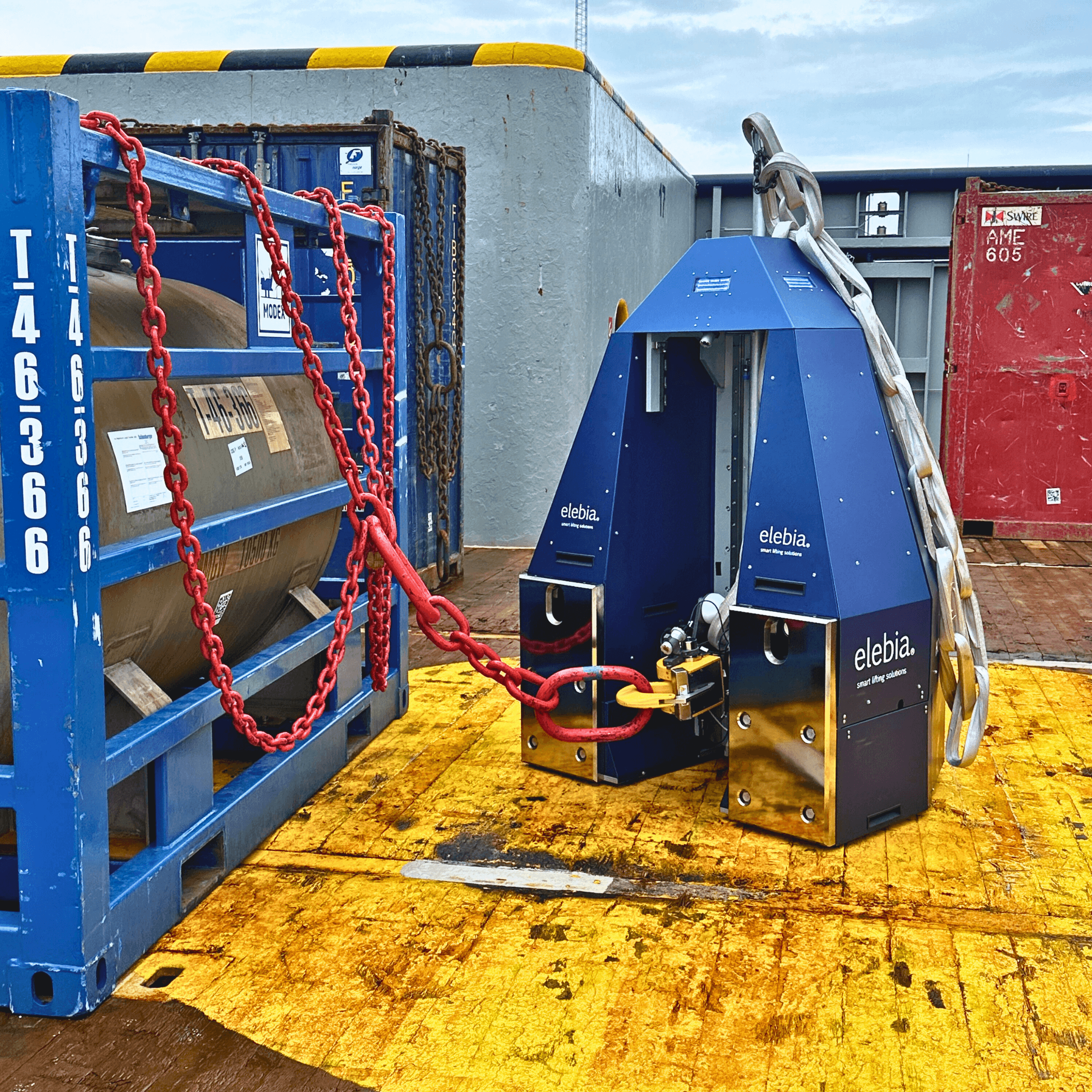

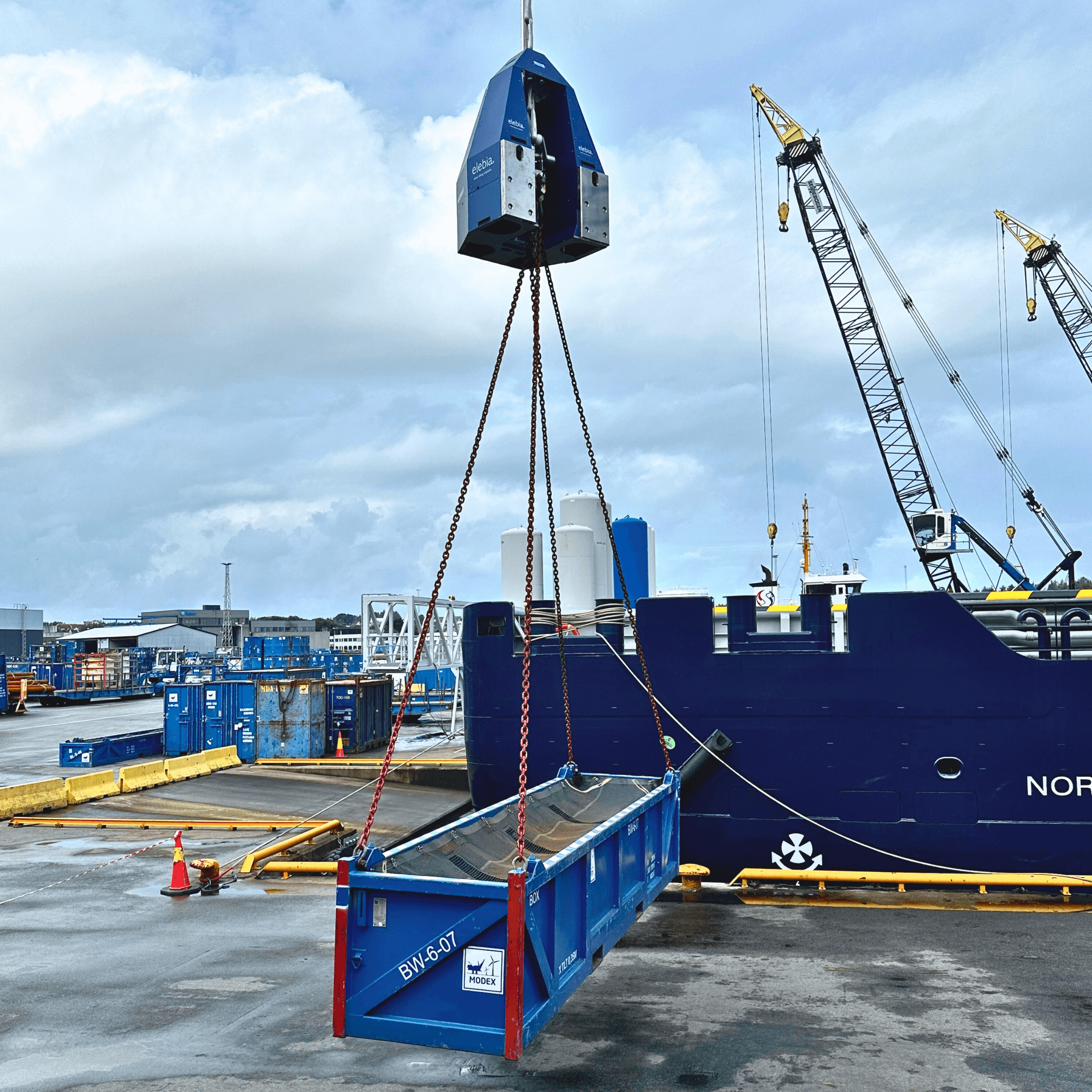

Offshore Containers with Unique Lifting Point Using Hookbot

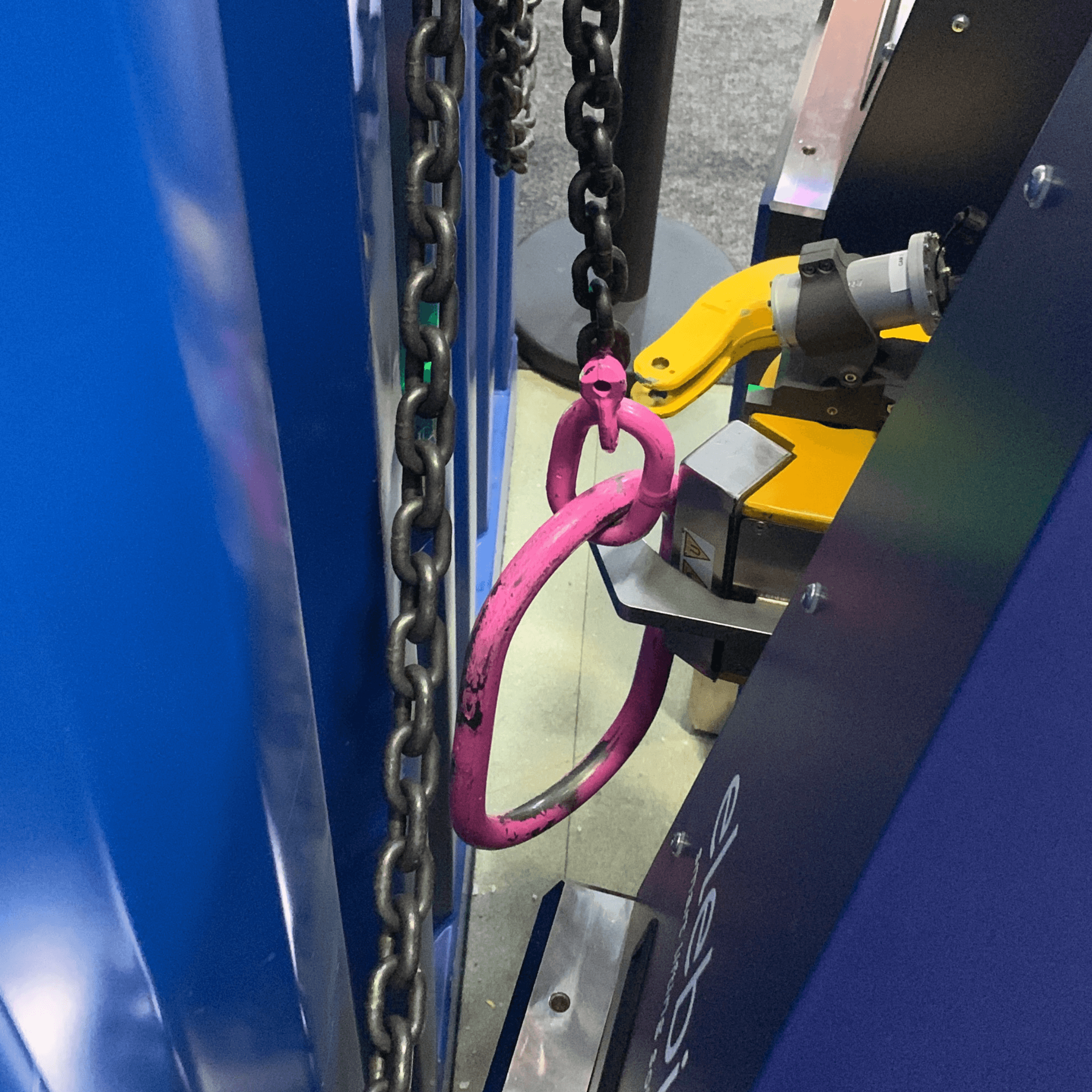

Open Top Container with Two Masterlinks and Hookbot Integration

Efficient Lifting with Textile Slings and Hookbot

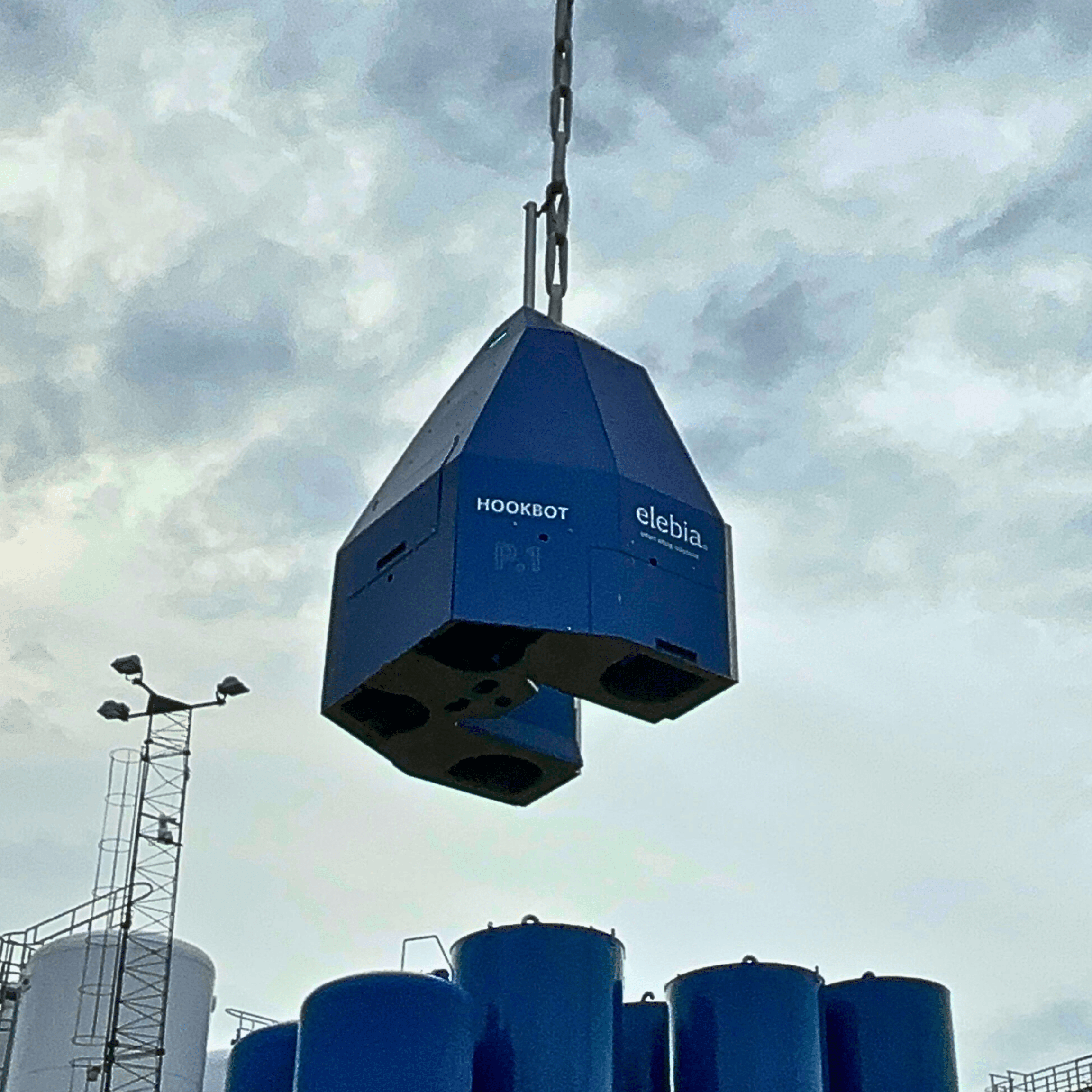

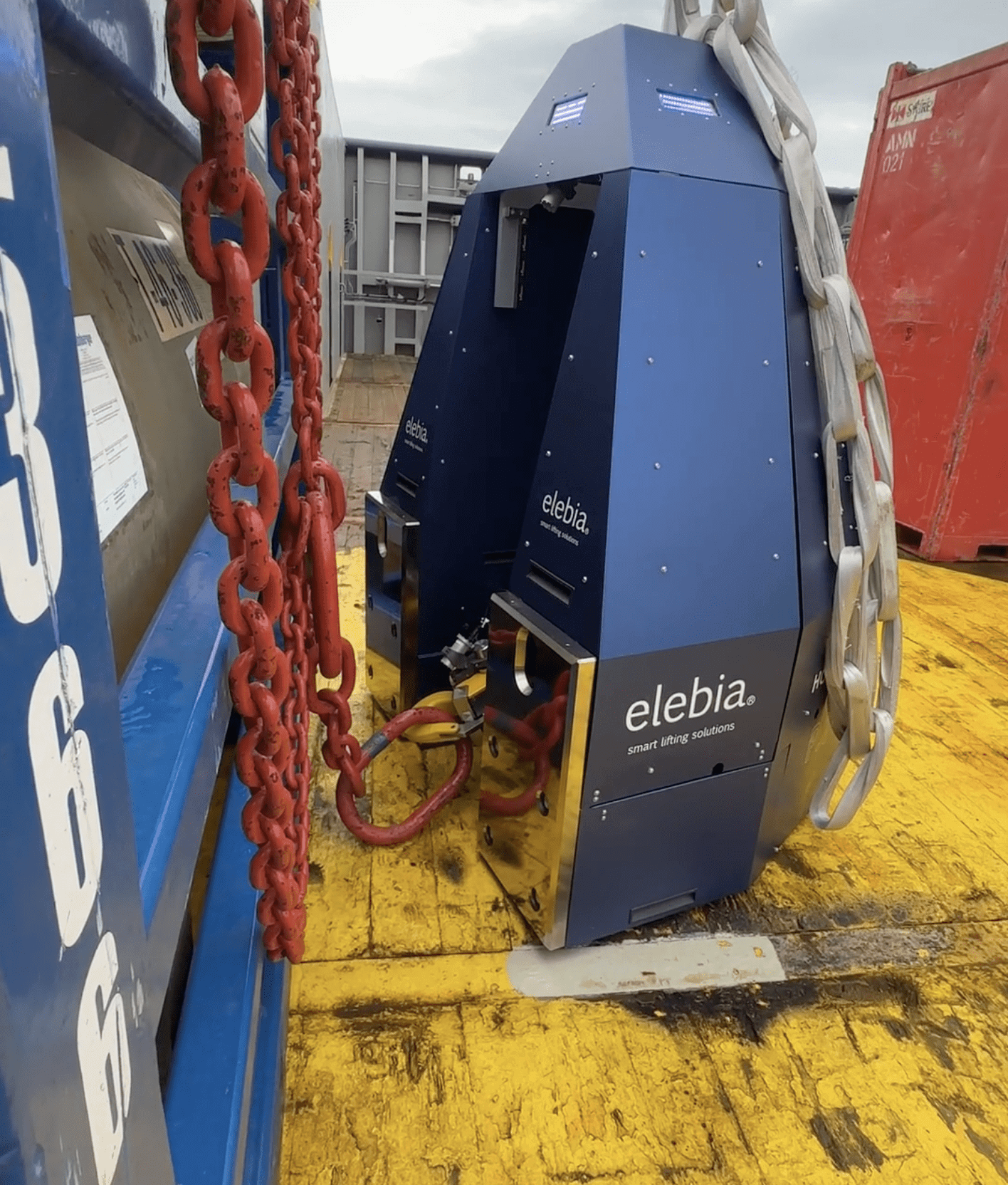

Hookbot p.1

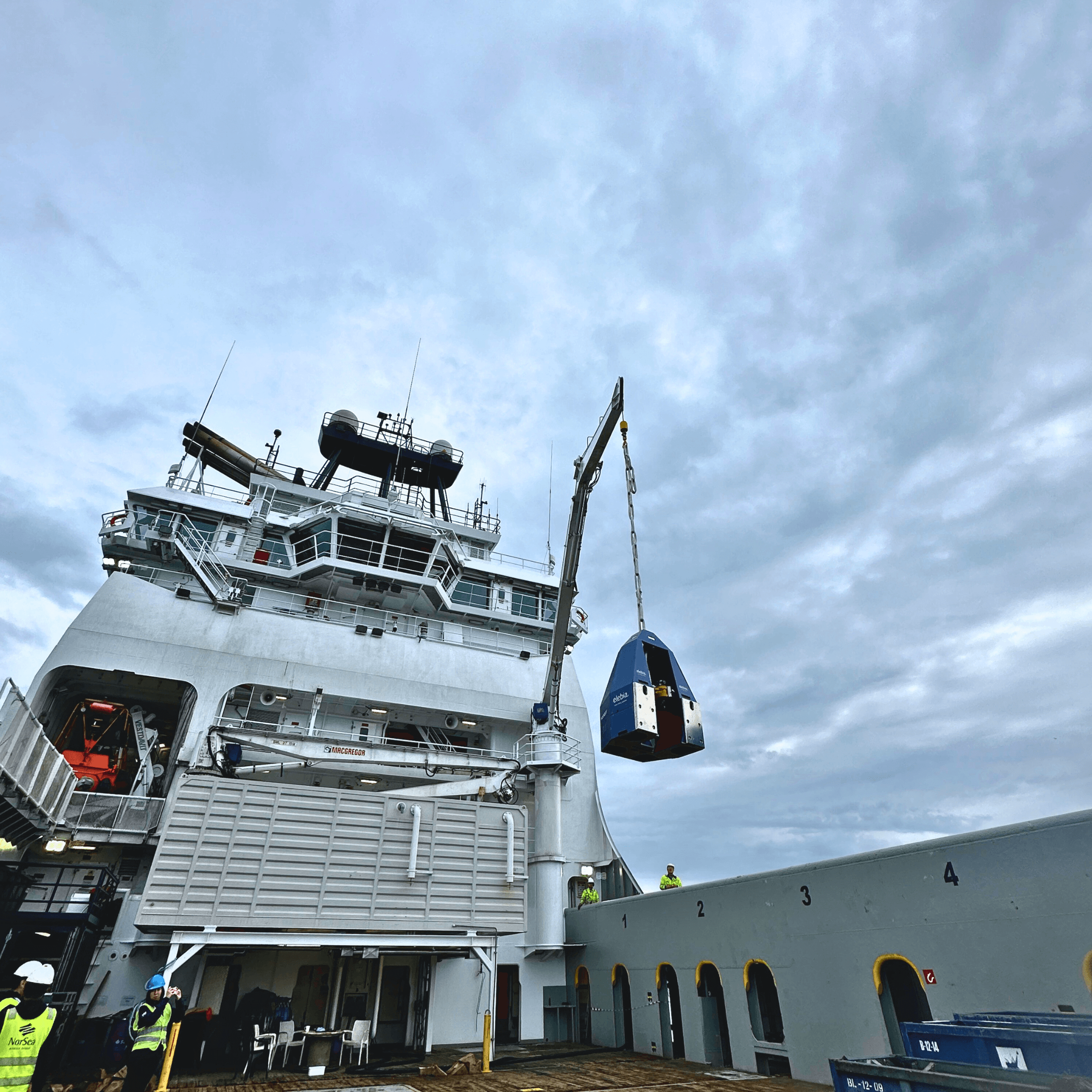

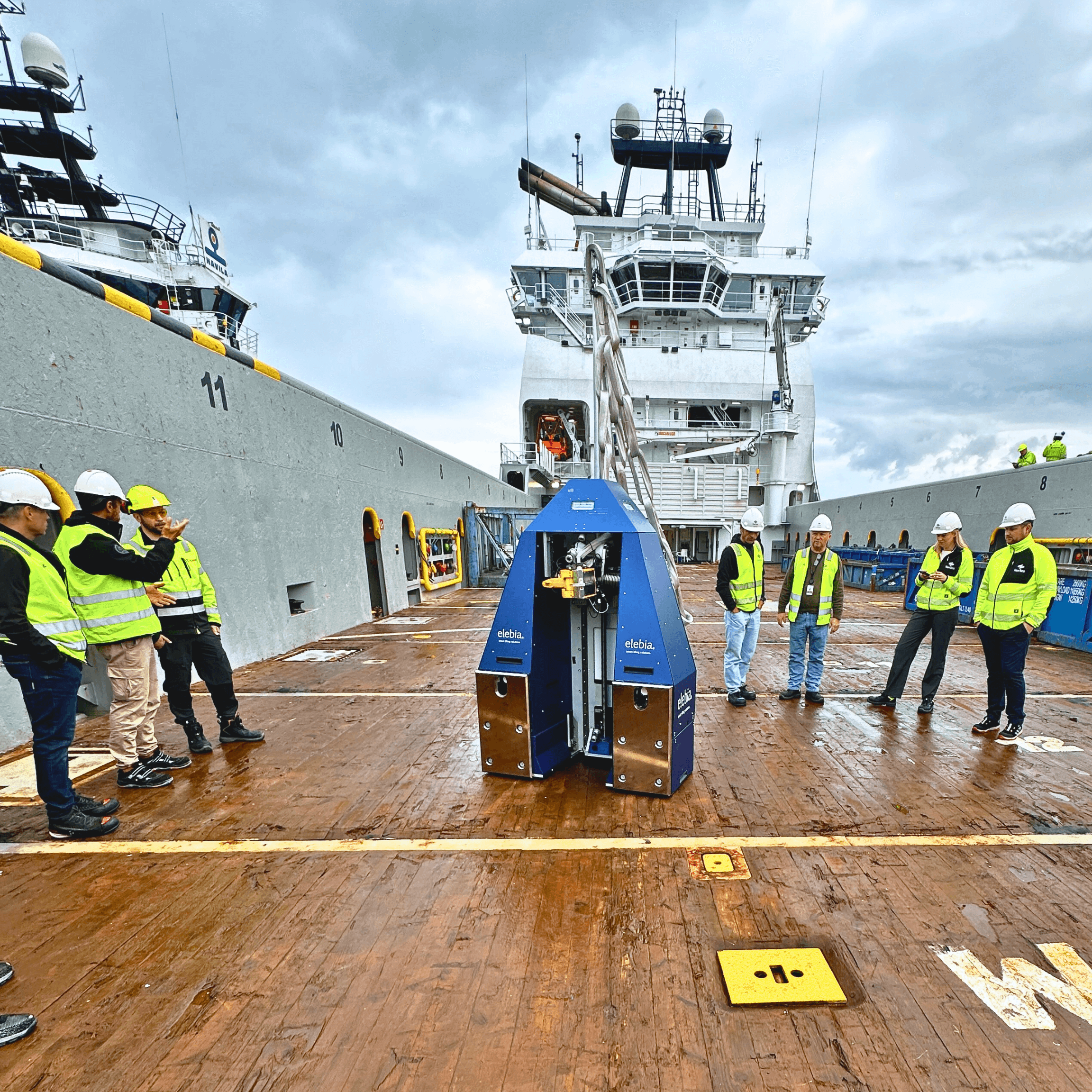

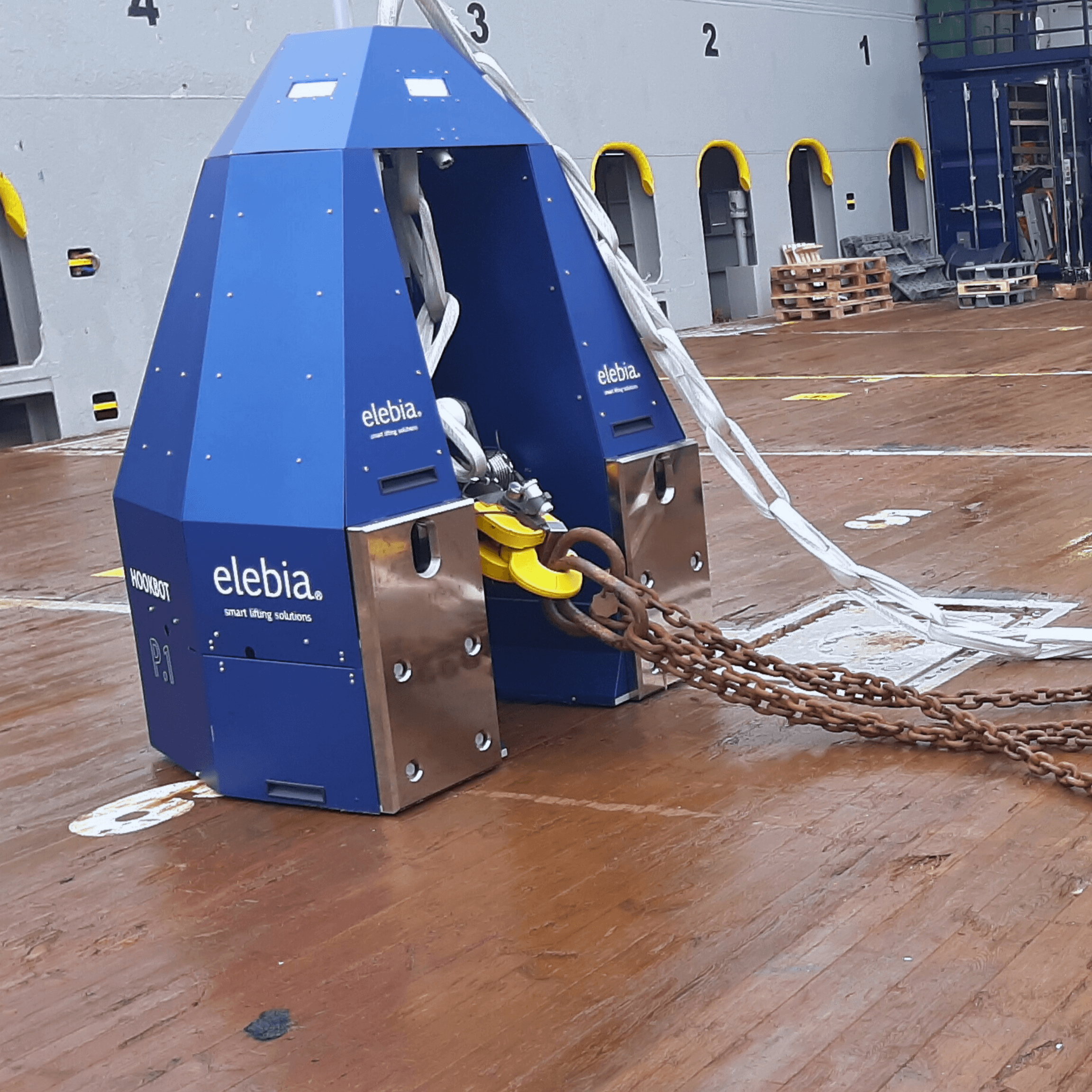

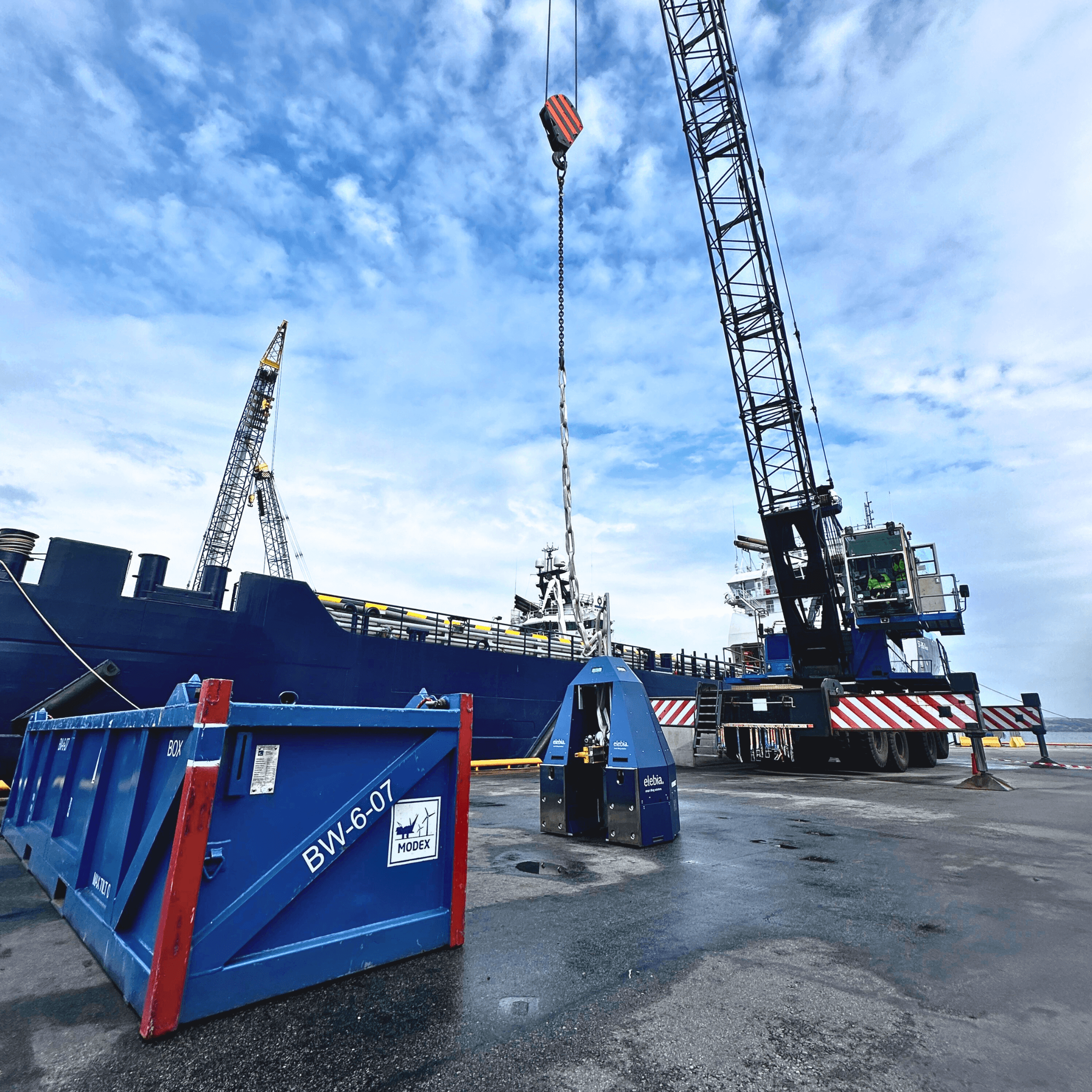

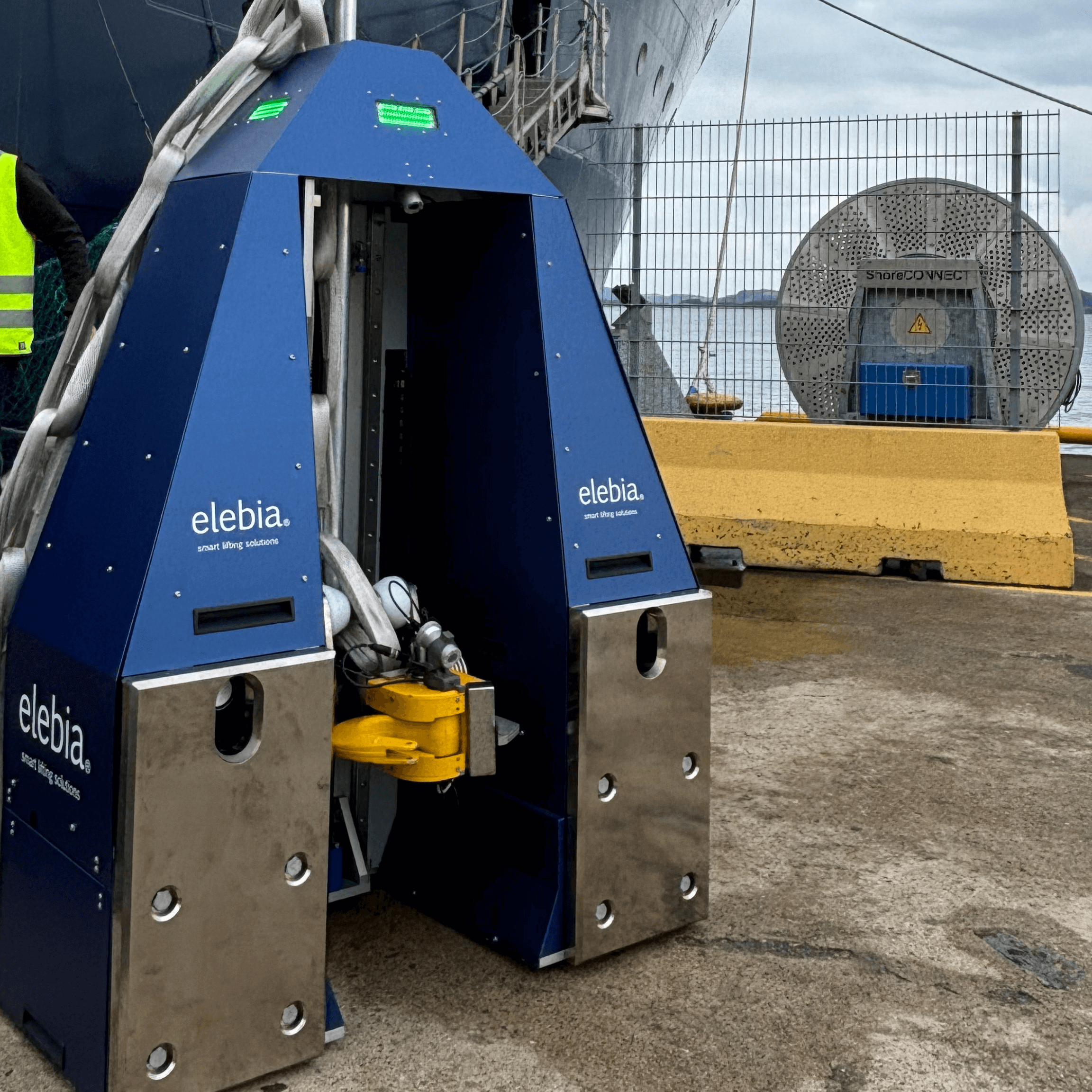

- It is larger, more robust, and has already undergone testing in an operational environment at the Port of Stavanger.

- Designed for use on offshore platforms, the Hookpot P.1 is a next-generation autonomous robot that moves smoothly over different surfaces, even in the presence of obstacles.

- The product is fully controlled remotely, reducing human involvement to zero and paving the way towards the ultimate goal of creating an unmanned platform for offshore logistics.

Testing the Hookbot p.1

Key Benefits of Elebia Hookbot

The Evolution of Offshore Lifting: The Hookbot Story

Quick FAQs about our Hookbot

What is the Hookbot and how does it benefit offshore operations?

The Hookbot is an automated lifting solution by Elebia that streamlines offshore operations by allowing remote control of hooks, increasing safety and efficiency in hazardous environments. This robot features omnidirectional movement, which allows control and movement from a remote location. Operators can manage both the robot’s movements and the hook’s attachment and release mechanisms remotely. The main goal is to eliminate the need for humans on deck during offshore operations, particularly in adverse weather conditions.

Can the Hookbot be used with different types of containers?

Yes, the Hookbot is compatible with various container types, designed for versatility in different lifting scenarios.

What safety features does the Hookbot include?

Hookbot includes safety features such as fail-safe locking mechanisms, remote monitoring, and alerts to ensure safe and controlled lifting.

How is the Hookbot controlled remotely?

The Hookbot can be operated with a remote control system, which allows precise handling from a safe distance.

What is the lifting capacity of the Hookbot?

The lifting capacity of the Hookbot depends on the model, but the evo20 hook it is equipped with can lift up to 20,000 kg. For more details, refer to Elebia’s specifications.

How do I schedule a demo of the Hookbot?

You can schedule a demo by contacting Elebia through the “Schedule a Demo” button in the website header or footer, or by emailing info@elebia.com.